Perforated metal mesh

- 产品描述

-

Product Introduction

Perforated metal is a material made by mechanically punching or laser cutting holes into various materials, such as metal sheets, stainless steel plates, aluminum sheets, galvanized sheets, and cold-rolled sheets. It is widely used in fields such as architectural decoration, filtration, sound insulation, protection, sieving, and other industrial applications.

Features of Perforated Metal

1.Diverse Materials: Different materials can be chosen based on requirements, such as corrosion-resistant stainless steel, lightweight aluminum, or other metals.

2.Variety of Hole Shapes: The holes can be round, square, rectangular, diamond-shaped, hexagonal, or even custom patterns.

3.Aesthetic Appeal: Suitable for decorative purposes in projects like building facades, ceilings, fences, etc.

4.Functionality: Provides ventilation, light transmission, anti-slip, sound absorption, and filtration capabilities.

5.Durable and Strong: Precision processing ensures high tensile strength and durability.

Common Applications of Perforated Metal

1.Industrial Uses: Used for screening and filtration in industries such as pharmaceuticals, food processing, and chemicals.

2.Architectural Uses: Decorative materials for ceilings, facades, stair anti-slip panels, etc.

3.Noise Reduction: Used as sound-absorbing panels and noise barriers.

4.Safety Protection: For fences, machine covers, security doors, protective nets, etc.

Manufacturing Process

Perforated metal is usually produced using CNC punching machines or laser cutting equipment. Holes are uniformly punched into the metal sheet based on pre-designed patterns. Afterward, additional processes like cutting, bending, coating, and welding are performed to create the finished product.

When selecting perforated metal, it is essential to determine parameters such as material, hole size, spacing, and thickness according to specific needs to achieve the desired results.

Specification Parameter Table

Hole Diameter (mm) Hole Spacing (mm) Plate Thickness (mm) Open Area (%) Common Materials 0.8 1.5 0.3-0.8 23% Stainless Steel, Aluminum, Cold Rolled Steel 1 2 0.5-1.0 20% Stainless Steel, Galvanized Steel, Aluminum 2 3 0.8-2.0 30% Stainless Steel, Aluminum, Copper 3 5 1.0-3.0 33% Galvanized Steel, Stainless Steel, Aluminum 5 8 1.0-4.0 40% Cold Rolled Steel, Stainless Steel, Aluminum 10 15 2.0-6.0 44% Stainless Steel, Galvanized Steel 20 30 3.0-10.0 50% Aluminum, Stainless Steel, Cold Rolled Steel 50 80 5.0-15.0 60% Stainless Steel, Aluminum, Galvanized Steel

We Support Customized Services Regardless Of Material And Model Please Tell Me Your Needs

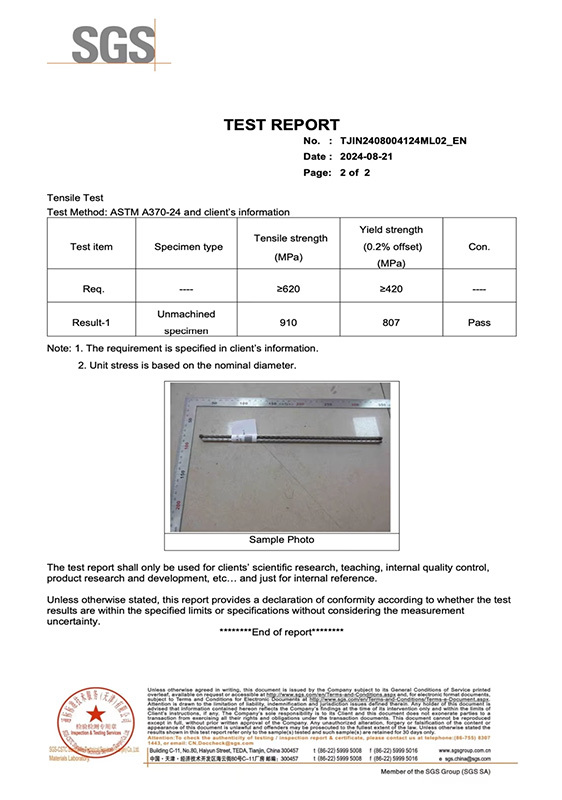

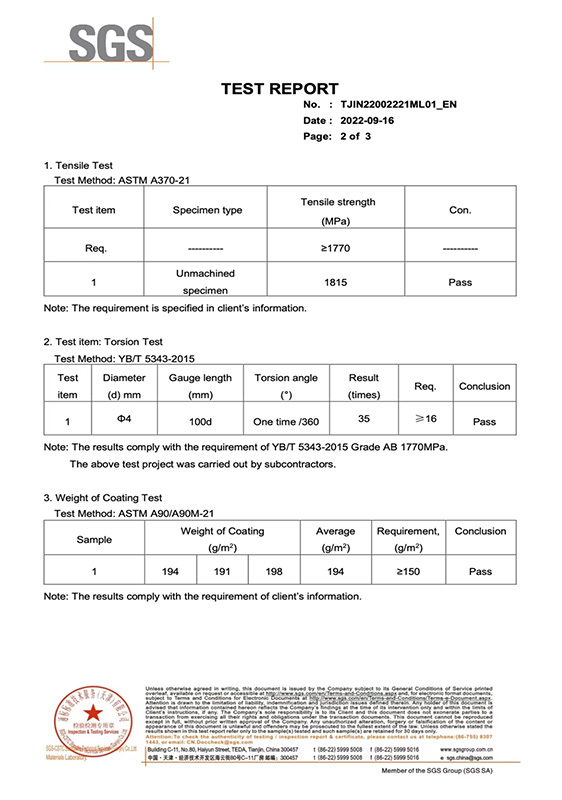

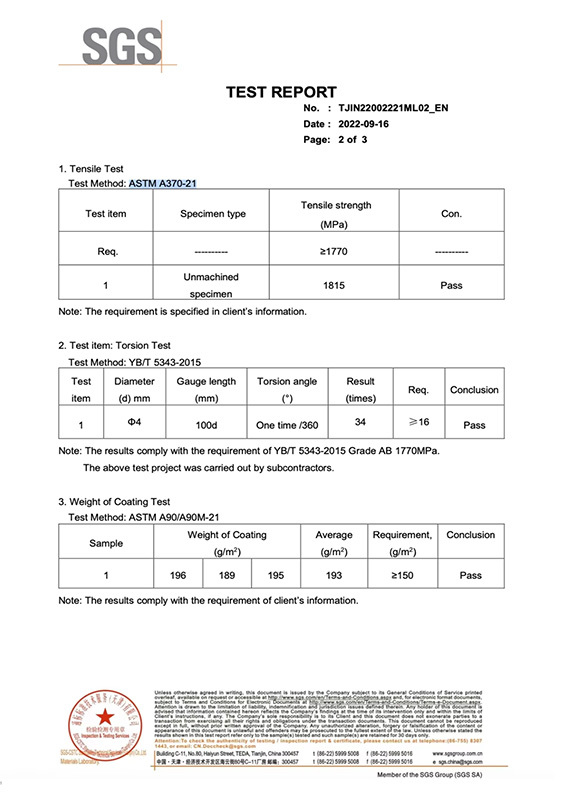

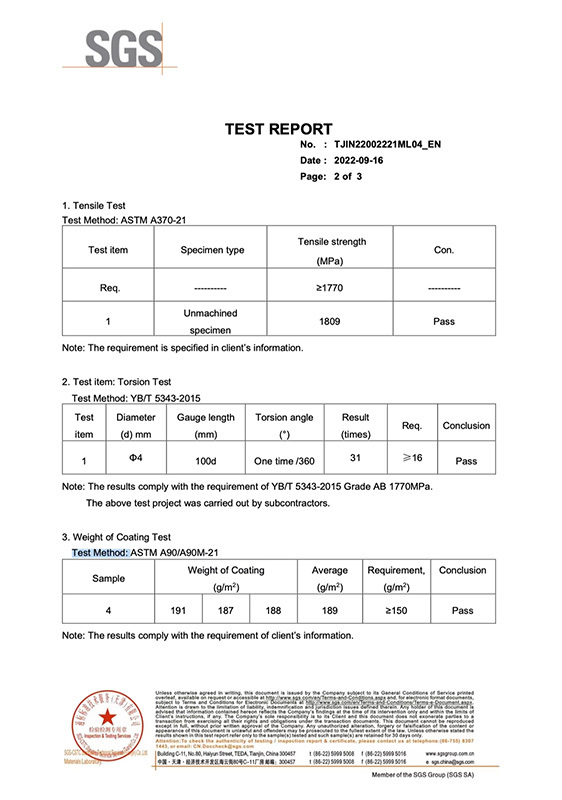

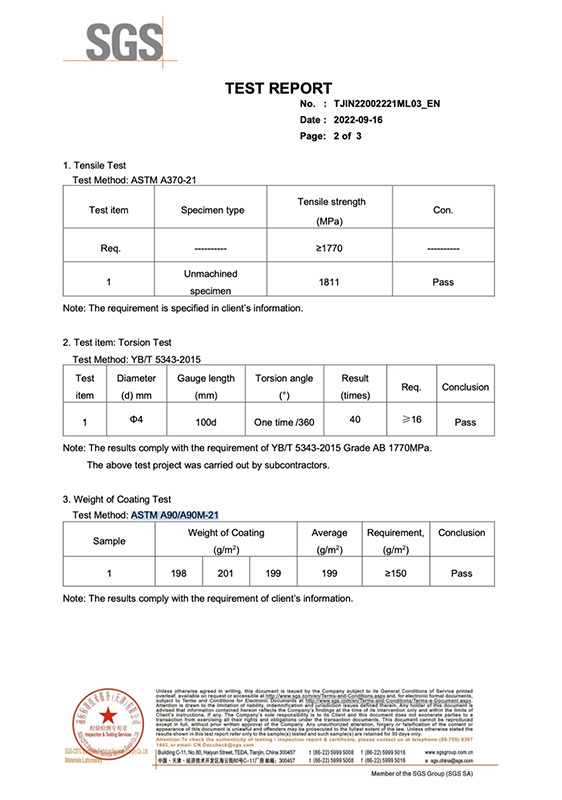

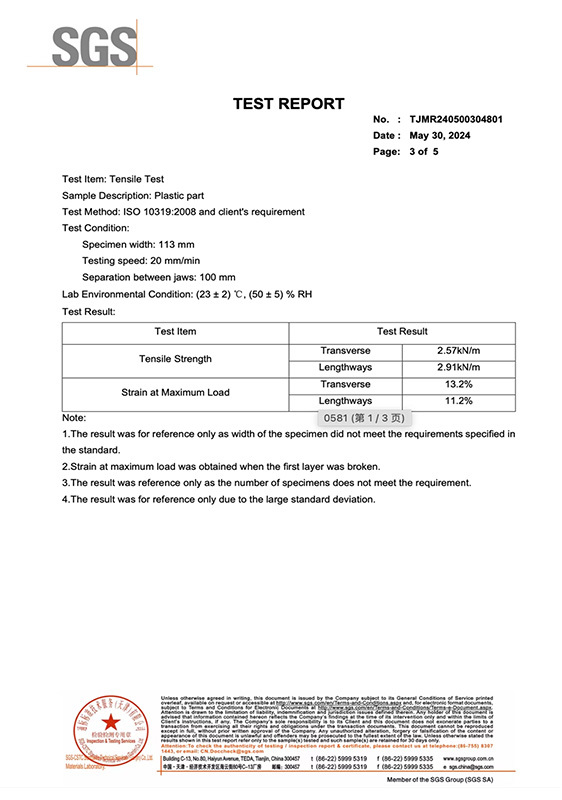

Qualifications

Company Introduction

Now our company has employees 83production machinery more than 70 sets, with a total area of 30,000 square meters, the production process instrict accordance with lSO9001: 2000 standards and certification.Our products include: Decoraive Wire Mesh, Diamond Metal Lath, Rib lath, Hy Rib Formwork, ConstructionExpanded Metal Mesh In Rol, Brick Mesh, Corner Bead, Fiberglass Mesh, Perforated Metal Sheet, ExpandedMetal Mesh, Welded Wire Mesh, Welded Mesh Panel, Fence Mesh, Stainless Steel Kind Kong Wire MeshExpanded Metal Mesh for Insert Netting, Aluminum Perforated Security Door Mesh, and so on.

Exhibition Updates

We are active in major exhibitions around the world and are committed to providing customers with professional metal mesh solutions. The guiding principle of company quality is "Quality is life" and " lmprove quality and no endless".in addition toestablishing the quality policy, quality procedures, but in all the plant into sophisticated detection equipment, tostrengthen inspection work, every second to achieve the maximum quide lines. And to "insist on doing is to dothe best"business philosophy, expanded to hearts of every employee, making our company continued prosperityand sustainable industry beyond the source.

Key words:

Related Products