Bag Filter

- 产品描述

-

The bag filter is a common industrial filtration equipment. Below is a detailed introduction:

Basic Principle

It uses a filter bag as the filtration medium. When fluid (liquid or gas) passes through the filter bag, impurities are trapped on the surface or inside the filter bag, thereby realizing fluid purification. The fluid enters through the filter inlet, is filtered by the filter bag, and then the clean fluid flows out through the outlet. Impurities remain in the bag. After filtering for a certain period or when the differential pressure threshold is reached, the filter bag can be replaced or cleaned.

Structural Composition

1.Housing: Generally cylindrical (vertical) or box-shaped (horizontal), made of materials such as carbon steel and stainless steel. It provides a filtration space and bears the working pressure.

2.Filter Bag: The core filtration component, commonly made of materials like polyester, polypropylene, and nylon. It comes in different precisions (e.g., 1μm - 800μm) and specifications, which can be selected according to filtration needs. The bag mouth usually has a ring (for sealing with the filter).

3.Support Basket: Placed inside the housing, it is used to support the filter bag, preventing the filter bag from deforming or breaking under fluid pressure, and ensuring the filtration area and effect.

4.Inlet/Outlet and Accessories: Includes a liquid inlet, liquid outlet, and drain port (for discharging impurities and residual liquid). It also has a pressure gauge interface (for monitoring the differential pressure before and after filtration) and a vent valve (for removing air inside the housing).

Features and Advantages

1.High Filtration Precision: By selecting filter bags of different precisions, it can effectively trap micro-particles to meet fine filtration requirements. For example, in the electronics industry, it can filter out tiny impurities in liquids to ensure product quality.

2.Large Processing Capacity: Different specifications (e.g., single-bag, multi-bag types) can be selected according to actual working conditions. Multi-bag filters enable parallel filtration, significantly increasing the fluid processing volume per unit time and adapting to large-scale production.

3.Easy Operation: Replacing the filter bag is relatively simple—just close the inlet and outlet valves and open the access door for replacement, making daily maintenance convenient. Some models even allow online filter bag replacement (without shutdown), reducing production downtime.

4.Wide Applicability: It can handle various fluids, including water, oils, and chemical liquids, and has good adaptability to fluids of different viscosities and temperatures (within a certain range). It is widely used in chemical, food, pharmaceutical, water treatment, and other industries.

Application Scenarios

1.Chemical Industry: Filters various chemical raw materials, intermediates, and finished products to remove impurities and ensure product quality (e.g., filtering coatings, inks, solvents).

2.Food and Beverage Industry: Filters fruit juices, alcoholic beverages, edible oils, etc., to remove pulp residues and suspended solids, improving product clarity and quality and meeting food hygiene requirements.

3.Pharmaceutical Industry: Filters liquid medicines, water injections, etc., during pharmaceutical production to ensure drug purity and safety, and strictly control impurity content.

4.Water Treatment: Used for side filtration of industrial circulating water, pre-treatment of wastewater (removing large-particle impurities), and advanced purification of drinking water. It protects subsequent equipment and improves water quality.

5.Automotive Manufacturing: Filters pre-painting treatment fluids and electrophoretic paints to ensure painting effects, making car body coatings even, aesthetic, and durable.

Selection Key Points

1.Fluid Properties: Consider the fluid’s chemical properties (e.g., corrosiveness—select suitable housing and filter bag materials), temperature (select temperature-resistant filter bag materials and pay attention to the housing’s temperature resistance), and viscosity (high viscosity may require a larger filtration area or lower flow rate).

2.Filtration Precision: Select a filter bag with corresponding precision based on the required purification level. Higher precision ensures better filtration effects but may affect flow rate and increase costs.

3.Processing Capacity: Calculate the required fluid flow rate, select single-bag or multi-bag types, and determine the number and specifications of filter bags to ensure the filter meets production rhythms.

4.Installation Space: Combine the space size of the on-site installation location to select vertical or horizontal types and appropriate overall dimensions, ensuring convenient installation, operation, and maintenance.

With its flexible structure and excellent filtration performance, the bag filter plays an important role in various links of industrial production, helping enterprises achieve efficient fluid purification and stable operation of production processes.

We Support Customized Services Regardless Of Material And Model Please Tell Me Your Needs

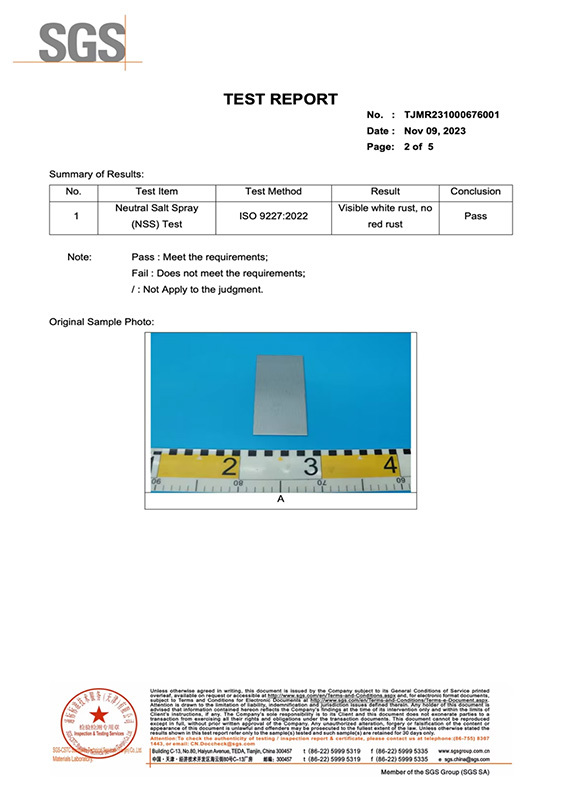

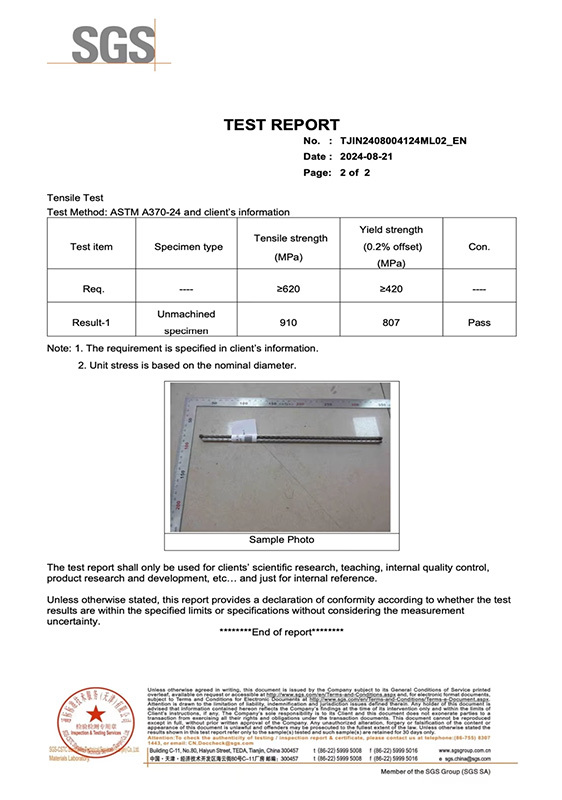

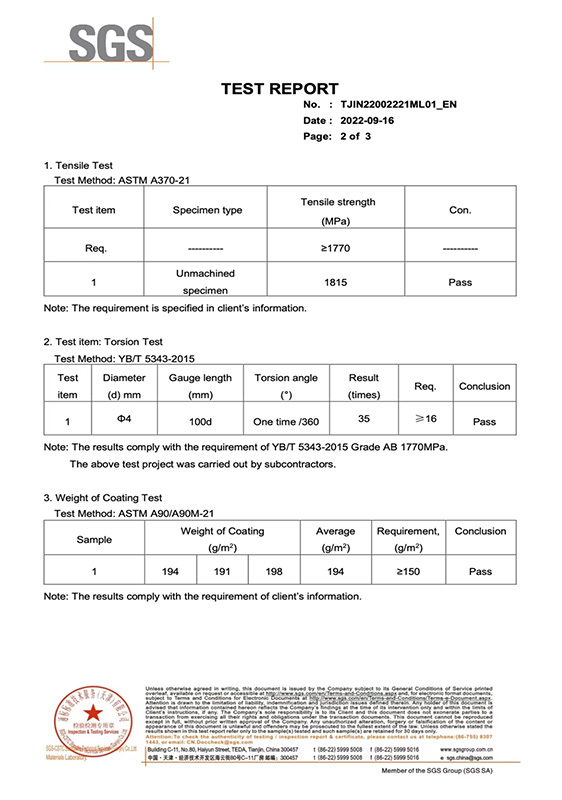

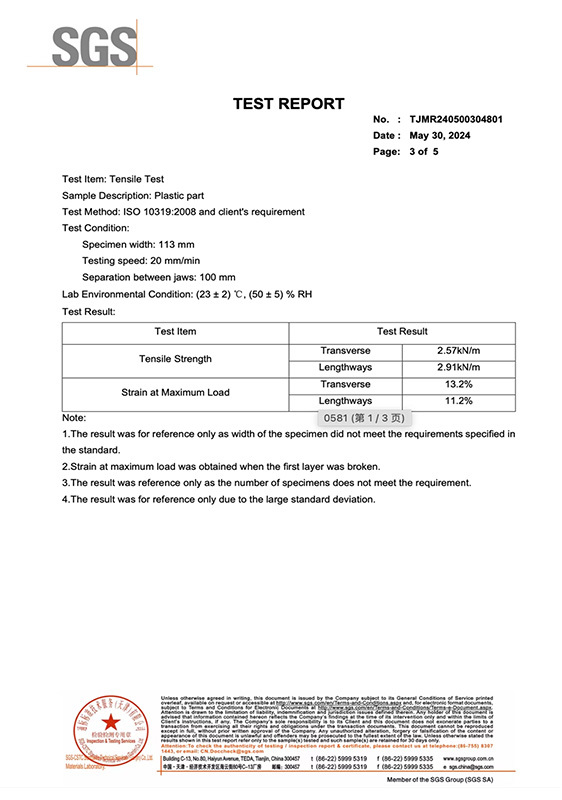

Qualifications

Company Introduction

Now our company has employees 83production machinery more than 70 sets, with a total area of 30,000 square meters, the production process instrict accordance with lSO9001: 2000 standards and certification.Our products include: Decoraive Wire Mesh, Diamond Metal Lath, Rib lath, Hy Rib Formwork, ConstructionExpanded Metal Mesh In Rol, Brick Mesh, Corner Bead, Fiberglass Mesh, Perforated Metal Sheet, ExpandedMetal Mesh, Welded Wire Mesh, Welded Mesh Panel, Fence Mesh, Stainless Steel Kind Kong Wire MeshExpanded Metal Mesh for Insert Netting, Aluminum Perforated Security Door Mesh, and so on.

Exhibition Updates

We are active in major exhibitions around the world and are committed to providing customers with professional metal mesh solutions. The guiding principle of company quality is "Quality is life" and " lmprove quality and no endless".in addition toestablishing the quality policy, quality procedures, but in all the plant into sophisticated detection equipment, tostrengthen inspection work, every second to achieve the maximum quide lines. And to "insist on doing is to dothe best"business philosophy, expanded to hearts of every employee, making our company continued prosperityand sustainable industry beyond the source.

Key words:

Related Products