Metal Grid Cable Tray

- 产品描述

-

The full name is metal grid cable tray, which is a tray used to support and protect cables and wires, and is an extension of traditional cable trays. The detailed introduction is as follows:

Structure and Manufacturing

1.Structure: Composed of crisscrossing horizontal and vertical metal strips, forming a regular grid pattern. Its open structure keeps cables exposed and visible.

2.Manufacturing: The raw material is steel wire, which is welded and formed using pulse spot welding machines. It then undergoes processes such as passivation treatment, pickling, and electrolytic polishing.

Material and Surface Treatment

1.Materials

●Common materials include galvanized carbon steel, plastic-sprayed carbon steel, stainless steel, and aluminum alloy。

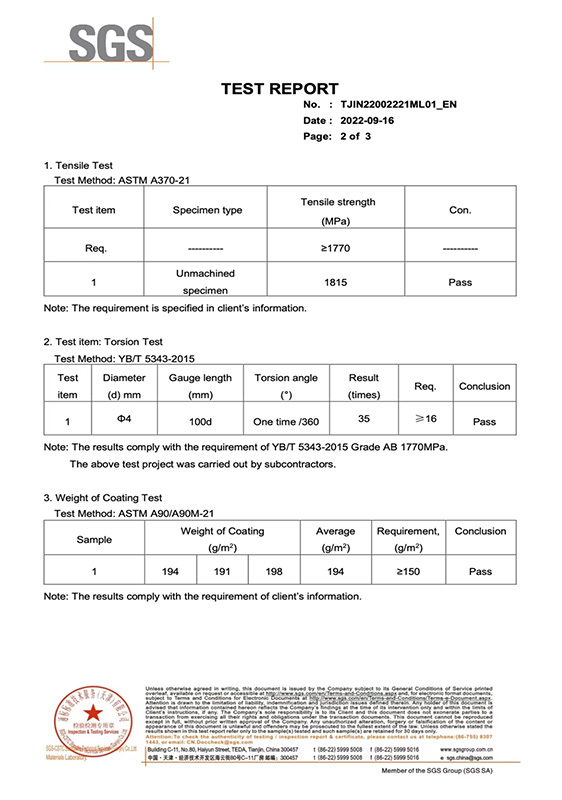

●Galvanized carbon steel trays: Feature good corrosion resistance and mechanical strength, suitable for general industrial and commercial buildings.

●Stainless steel trays: Offer excellent corrosion resistance, used in humid and highly corrosive environments.

●Aluminum alloy trays: Lightweight, suitable for places with requirements for weight reduction and aesthetics.

2.Surface Treatment

●Electro-galvanizing: The zinc layer is relatively thin, suitable for indoor use.

●Hot-dip galvanizing: The zinc layer thickness ranges from 60 to 80 microns, with strong corrosion resistance, suitable for outdoor environments, etc.

●Stainless steel: Grades such as 201, 202, 304, 316, and 316L have inherent good corrosion resistance.

●Plastic spraying: A plastic coating is sprayed on the tray surface, available in various colors, providing both corrosion resistance and aesthetics.

Specifications

Height:Common heights: 30mm, 54mm, 80mm, 105mm, 150mm, etc.

Width:When the tray height is 30mm or 54mm: Width options include 50mm, 100mm, 150mm, 200mm, 300mm, 400mm, 450mm, 500mm, 600mm.

When the tray height is 105mm or 150mm: Width options include 100mm, 150mm, 200mm, 300mm, 400mm, 500mm.

Length:Typically 3000mm.

Naming Convention:The specification is named as "CM" + length + "/" + width, e.g., CM105/300.

Features

1.Convenient and flexible installation: No complex customized components are required; it can be freely cut and assembled on-site, and quickly built into structures such as right-angle, T-shaped, and cross-shaped configurations, significantly shortening installation time.

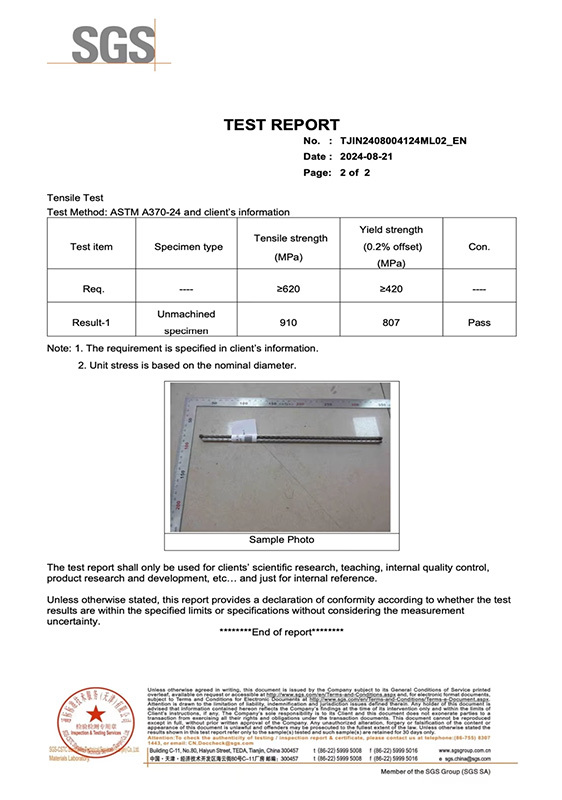

Excellent ventilation and heat dissipation: The open grid structure facilitates heat dissipation, preventing cables from performance degradation due to overheating and extending cable service life.2.Strong load-bearing capacity: Adopting high-quality steel wires of 4–6 millimeters, and through special welding processes, the weld joints can withstand a tension of 500 kilograms. It can support cables of various thicknesses and resist external impact and vibration.

3.Easy maintenance and inspection: Cables are clearly visible, making it easy to add/remove equipment or adjust cables, improving maintenance efficiency and reducing costs.

4.Lightweight: Its self-weight is only about 1/5 that of traditional cable trays, reducing the load on building structures.

5.High cost-effectiveness: Saves costs of secondary repeated investment, and makes the wiring system and surrounding environment cleaner and more aesthetically pleasing.

Application Scenarios

1.Data centers: Adapt to the needs of dense cables and frequent upgrades, distribute cables in an orderly manner, and avoid overheating and signal interference.

Industrial plants: Galvanized steel or stainless steel trays, with corrosion resistance and high strength, can cope with harsh environments, provide reliable protection for cables, and meet high-load wiring requirements.2.Commercial buildings: Can separate and lay low-voltage and high-voltage circuits to avoid electromagnetic interference; aluminum alloy trays can also meet the load-bearing restrictions and aesthetic requirements of high-rise buildings.

3.Equipment rooms: Ensure the stable operation of cables, reduce equipment failure rates, and improve system upgrade and maintenance capabilities.

We Support Customized Services Regardless Of Material And Model Please Tell Me Your Needs

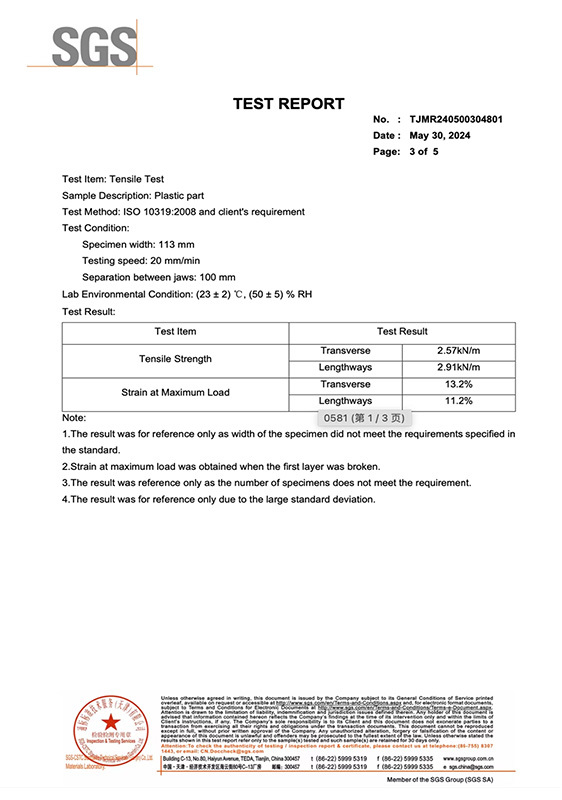

Qualifications

Company Introduction

Now our company has employees 83production machinery more than 70 sets, with a total area of 30,000 square meters, the production process instrict accordance with lSO9001: 2000 standards and certification.Our products include: Decoraive Wire Mesh, Diamond Metal Lath, Rib lath, Hy Rib Formwork, ConstructionExpanded Metal Mesh In Rol, Brick Mesh, Corner Bead, Fiberglass Mesh, Perforated Metal Sheet, ExpandedMetal Mesh, Welded Wire Mesh, Welded Mesh Panel, Fence Mesh, Stainless Steel Kind Kong Wire MeshExpanded Metal Mesh for Insert Netting, Aluminum Perforated Security Door Mesh, and so on.

Exhibition Updates

We are active in major exhibitions around the world and are committed to providing customers with professional metal mesh solutions. The guiding principle of company quality is "Quality is life" and " lmprove quality and no endless".in addition toestablishing the quality policy, quality procedures, but in all the plant into sophisticated detection equipment, tostrengthen inspection work, every second to achieve the maximum quide lines. And to "insist on doing is to dothe best"business philosophy, expanded to hearts of every employee, making our company continued prosperityand sustainable industry beyond the source.

Key words:

Related Products