Perforated Metal Mesh For Painting Work

- 产品描述

-

Product Introduction

Perforated Metal Mesh are used in painting work; the holes allow excess paint to drip off rollers or brushes, ensuring even paint distribution. The perforations also help keep tools organized and dry while reducing paint waste.

Metal Mesh Plate for Paint Rollers

The metal mesh plate for paint rollers is a commonly used tool in paint application. Its main function is to help achieve even paint coating and prevent excessive paint usage. Typically installed inside the roller or as part of the roller itself, the metal mesh plate can squeeze out excess paint through its mesh structure, ensuring the paint layer during brushing is even and properly dosed.

When using a paint roller, the metal mesh plate can help you:

Prevent paint buildup: When the roller dips into the paint bucket, the metal mesh plate scrapes off excess paint, avoiding the roller absorbing too much paint.

Improve construction efficiency: Even paint distribution reduces the need for re-coating, saving time and materials.

Enhance painting results: The mesh openings of the metal plate help distribute paint evenly across the roller surface, ensuring a smooth and fine coating.

During use, simply place the paint roller on the metal mesh plate and rotate or roll it to squeeze out excess paint—this ensures you can achieve an even, smooth finish.

Perforated Mesh

Perforated mesh is a porous material made from various materials (such as metal plates, stainless steel plates, aluminum plates, galvanized plates, cold-rolled plates, etc.) through mechanical punching or laser cutting. It is widely used in architectural decoration, filtration, sound insulation, protection, screening, and other industrial fields.

Manufacturing Process

The production of perforated mesh generally uses CNC punch presses or laser cutting machines to punch holes evenly on metal sheets according to preset hole patterns. After that, it undergoes subsequent processes such as cutting, bending, spraying, and welding to form the finished product.

When selecting perforated mesh, parameters such as material, hole diameter, hole spacing, and thickness should be determined based on actual needs to achieve the desired application effect.

Specification parameter table

aperture (mm) hole spacing (mm) plate thickness (mm) open area ratio (%) Common materials 0.8 1.5 0.3-0.8 23% Stainless steel, aluminum plate, cold-rolled steel plate 1 2 0.5-1.0 20% Stainless steel, galvanized sheet, aluminum sheet 2 3 0.8-2.0 30% Stainless steel, aluminum plate, copper plate 3 5 1.0-3.0 33% Galvanized sheet, stainless steel, aluminum sheet 5 8 1.0-4.0 40% Cold rolled steel plate, stainless steel, aluminum plate 10 15 2.0-6.0 44% Stainless steel, galvanized sheet 20 30 3.0-10.0 50% Aluminum plate, stainless steel, cold-rolled steel plate 50 80 5.0-15.0 60% Stainless steel, aluminum plate, galvanized plate

We Support Customized Services Regardless Of Material And Model Please Tell Me Your Needs

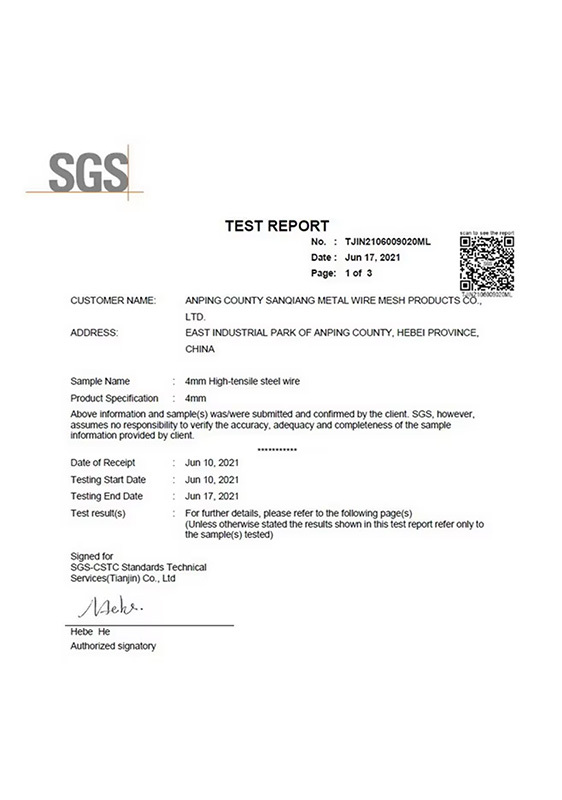

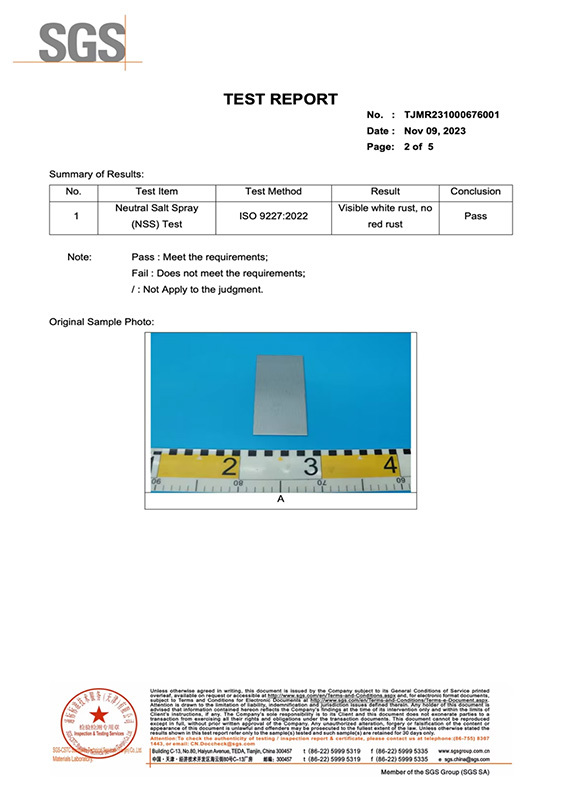

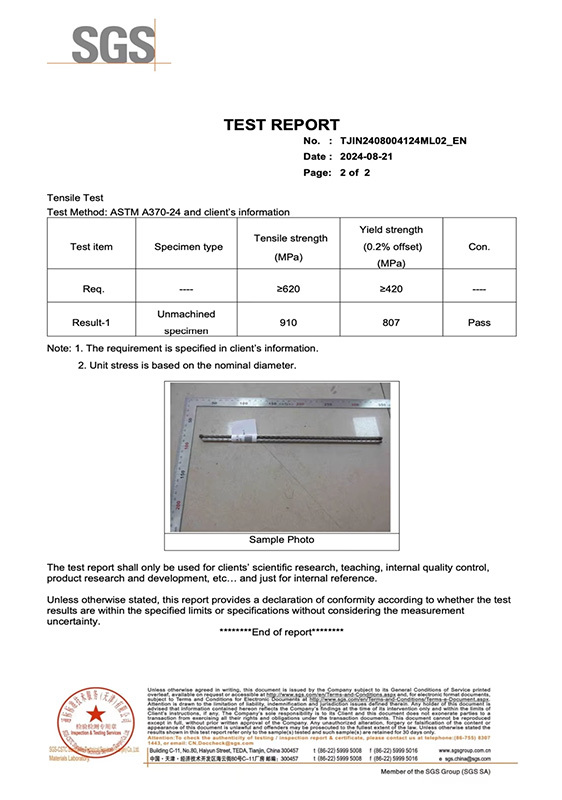

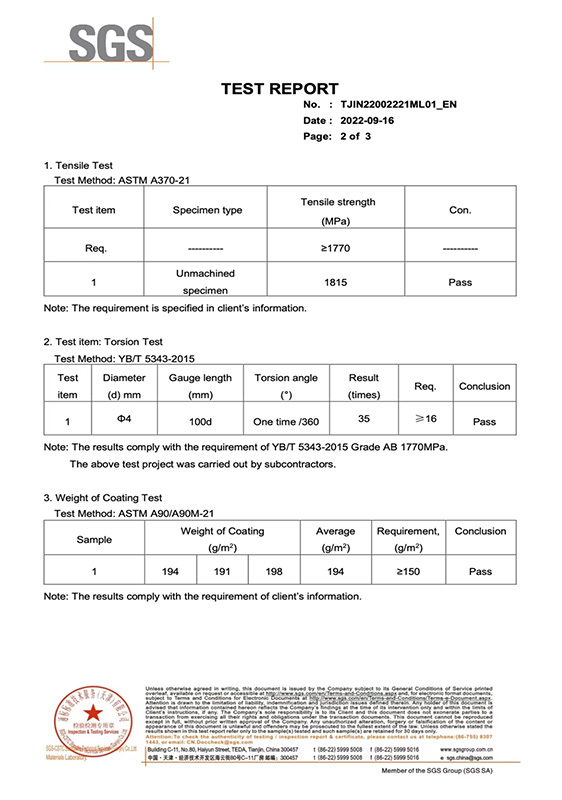

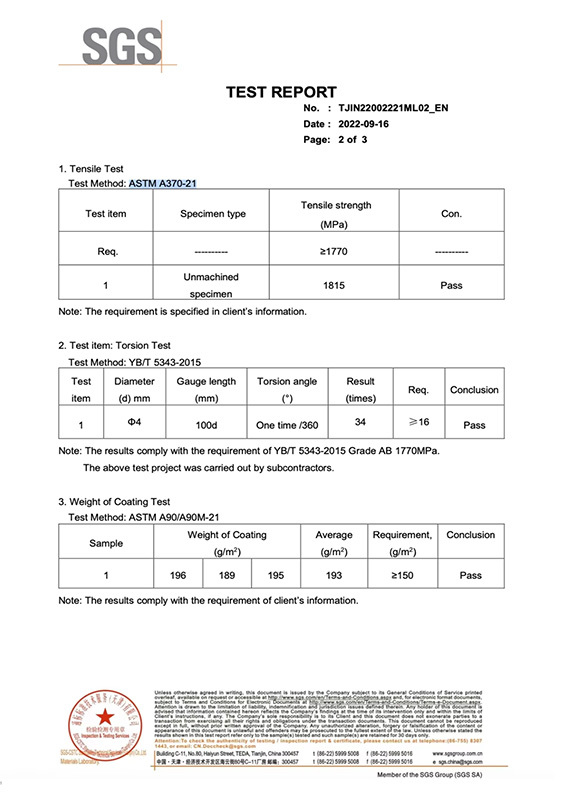

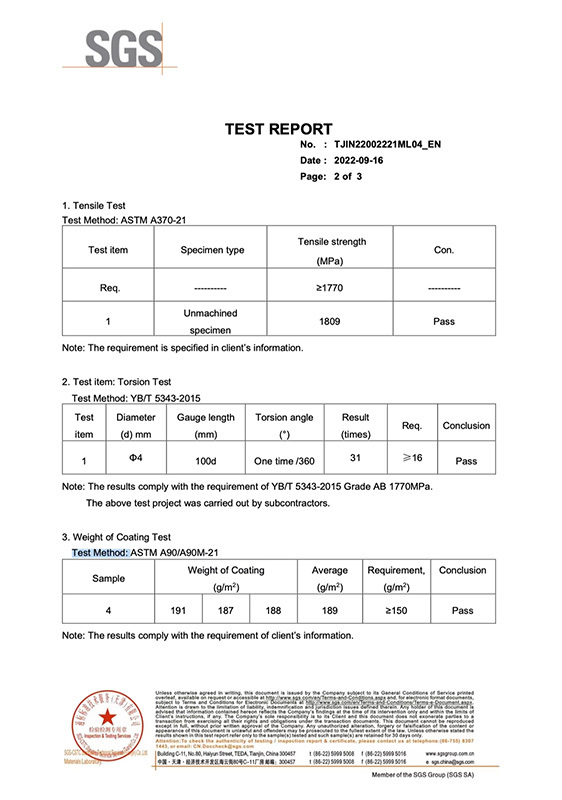

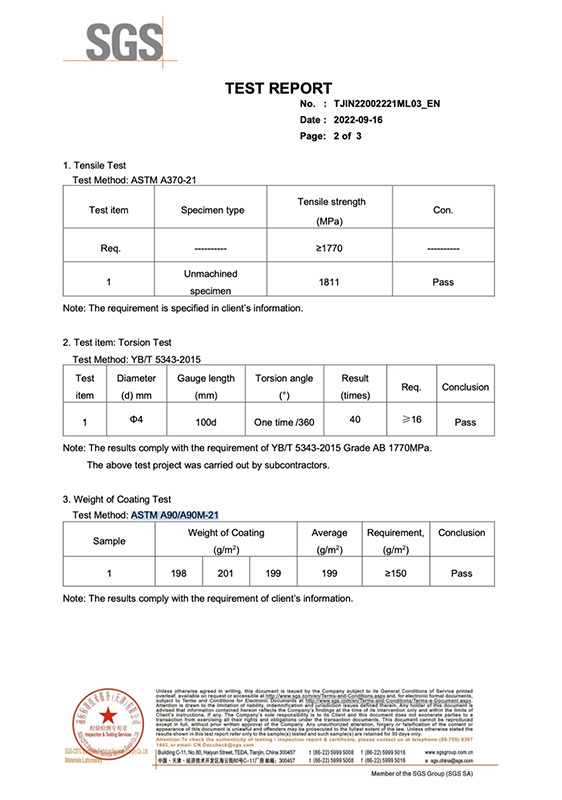

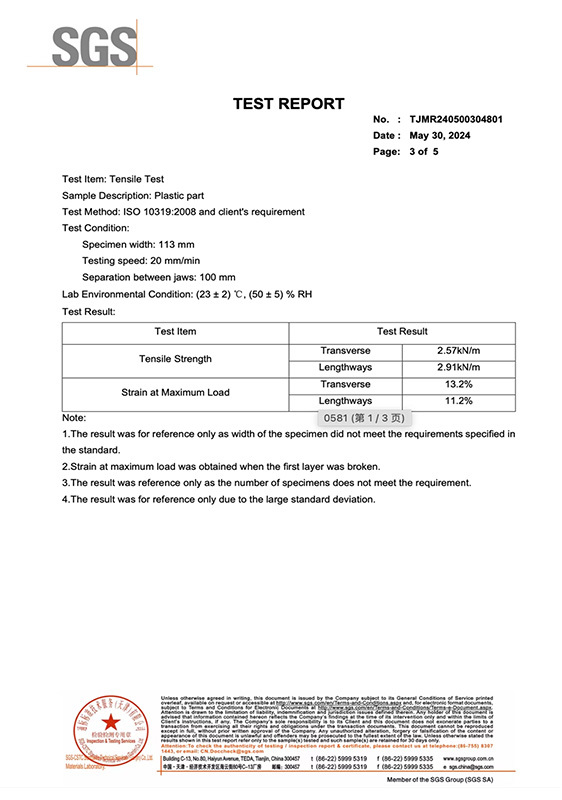

Qualifications

Company Introduction

Now our company has employees 83production machinery more than 70 sets, with a total area of 30,000 square meters, the production process instrict accordance with lSO9001: 2000 standards and certification.Our products include: Decoraive Wire Mesh, Diamond Metal Lath, Rib lath, Hy Rib Formwork, ConstructionExpanded Metal Mesh In Rol, Brick Mesh, Corner Bead, Fiberglass Mesh, Perforated Metal Sheet, ExpandedMetal Mesh, Welded Wire Mesh, Welded Mesh Panel, Fence Mesh, Stainless Steel Kind Kong Wire MeshExpanded Metal Mesh for Insert Netting, Aluminum Perforated Security Door Mesh, and so on.

Exhibition Updates

We are active in major exhibitions around the world and are committed to providing customers with professional metal mesh solutions. The guiding principle of company quality is "Quality is life" and " lmprove quality and no endless".in addition toestablishing the quality policy, quality procedures, but in all the plant into sophisticated detection equipment, tostrengthen inspection work, every second to achieve the maximum quide lines. And to "insist on doing is to dothe best"business philosophy, expanded to hearts of every employee, making our company continued prosperityand sustainable industry beyond the source.

Key words:

Related Products