Nail

- 产品描述

-

Iron nails are common fasteners widely used in various fields such as construction, carpentry, and decoration.

Structural Components

1.Nail Head: Usually located at one end of the iron nail, it has a larger area than the shank. Its function is to withstand the impact force of tools like hammers when the nail is being driven in. At the same time, it prevents the nail from sinking completely into the fixed material. It also plays a certain decorative and protective role. For example, in furniture making, an aesthetically pleasing nail head can make the furniture surface look neater.

2.Nail Shank: It is the main part of the iron nail, generally cylindrical. Some nail shanks have a smooth surface, while others have threads (such as spiral nails). Iron nails with smooth shanks are easy to drive into soft materials quickly, while those with threaded shanks can increase the friction with the material, making the fixing more secure.

3.Nail Tip: The pointed part of the iron nail is usually designed to be sharp, aiming to easily penetrate the fixed material and reduce the resistance when driving in.

Materials

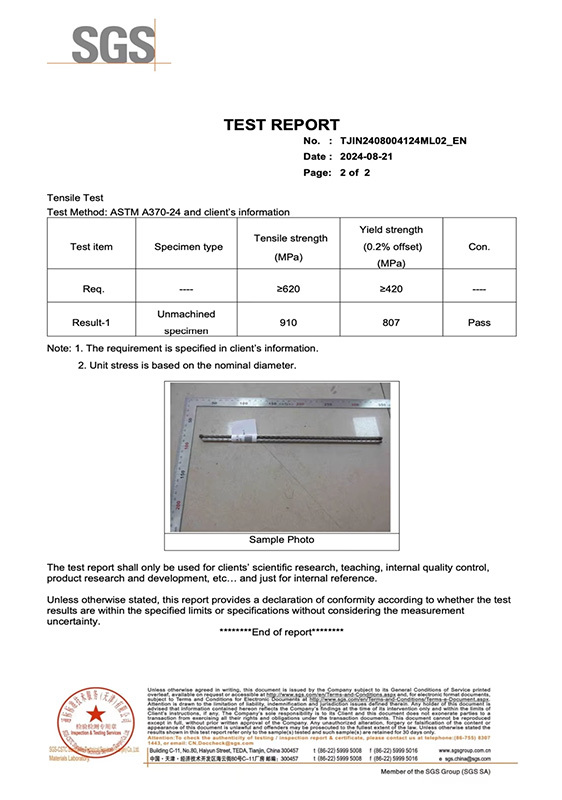

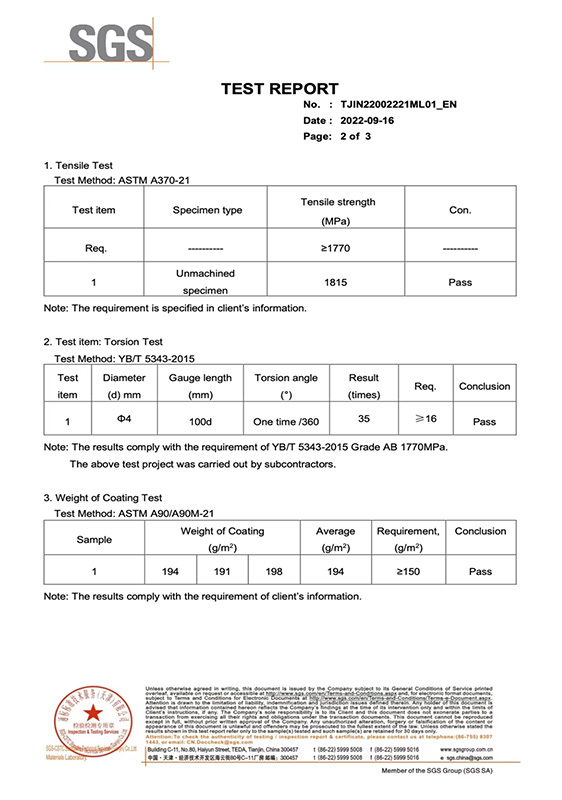

Iron nails are mostly made of carbon steel. To enhance their rust - and corrosion - resistance, their surfaces are often treated. Common treatment methods include galvanizing (including hot - dip galvanizing and cold - galvanizing), copper plating, and painting. Hot - dip galvanizing has a better rust - prevention effect and is suitable for use in outdoor or humid environments; cold - galvanizing has a relatively lower cost and can also provide good rust - prevention in general indoor environments.

Types and Applications

1.Common Round Nails: The most common type of iron nails, with a simple structure and wide applications. In carpentry, they are used for splicing wood and assembling furniture frames; in construction, they can be used to temporarily fix some components.

2.Corrugated Nails: The shank has spiral threads, and the nail head is relatively large. They are mainly used to fix corrugated roofing materials such as asbestos tiles and color steel plates. The spiral threads can increase the stability after driving in, and the large nail head can better cover the corrugated gaps, playing the roles of waterproofing and stabilizing.

3.Coil Nails (Strip Nails): Multiple round nails are connected together by metal wires or plastic strips to form a coil or a row. Special coil nail guns are required for use, which can achieve fast and continuous nailing, improving work efficiency. They are often used for large - scale plate fixing in building decoration, such as ceiling installation and wooden door and window installation.

4.Square - Head Self - Tapping Screws (can also be classified as a special type of iron nails): The head is square, and the shank has threads. They do not require pre - tapping in the material and can tap into soft materials such as wood and plastic by themselves. In scenarios such as furniture manufacturing and small woodworking projects, they are used to achieve precise and firm connections, and are convenient for later disassembly and adjustment.

Usage Precautions

Select the appropriate type and specification of iron nails according to the material, thickness of the fixed material, and actual usage requirements. For example, do not use overly thick and long iron nails to fix thin plate materials.

When using a hammer to drive in iron nails, pay attention to the posture of holding the nail and the striking force to avoid injuring fingers or causing the nail to bend or break.

When using iron nails in humid environments or outdoors, try to choose iron nails with good rust - resistance to extend their service life.

We Support Customized Services Regardless Of Material And Model Please Tell Me Your Needs

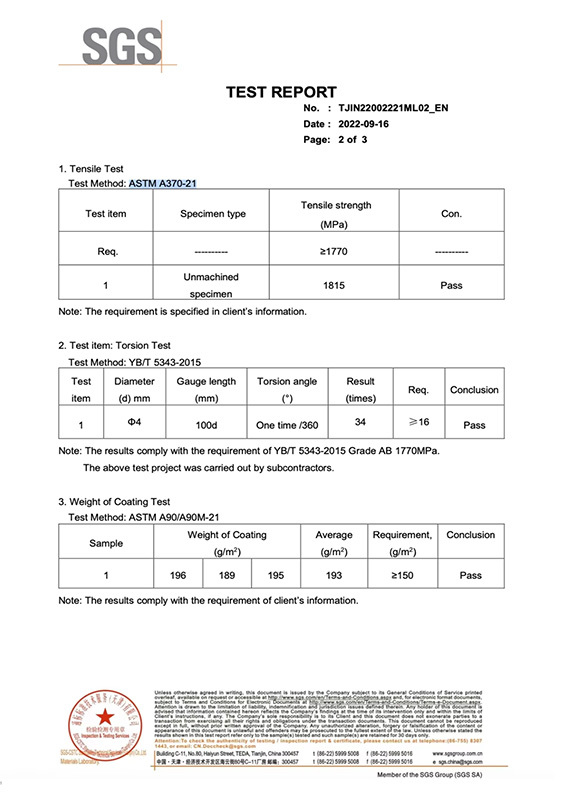

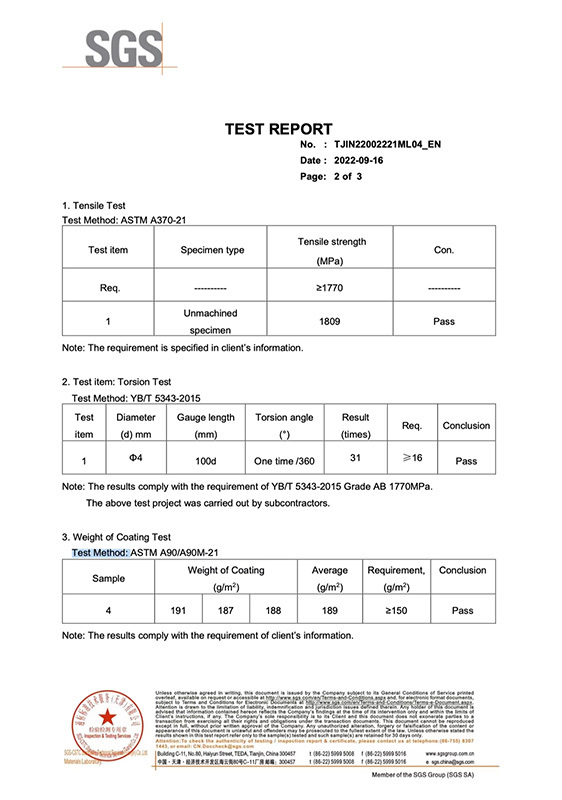

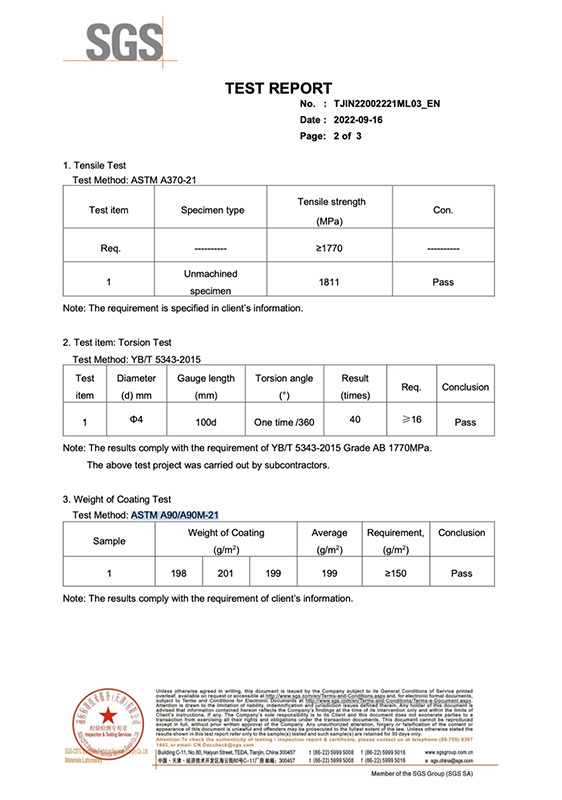

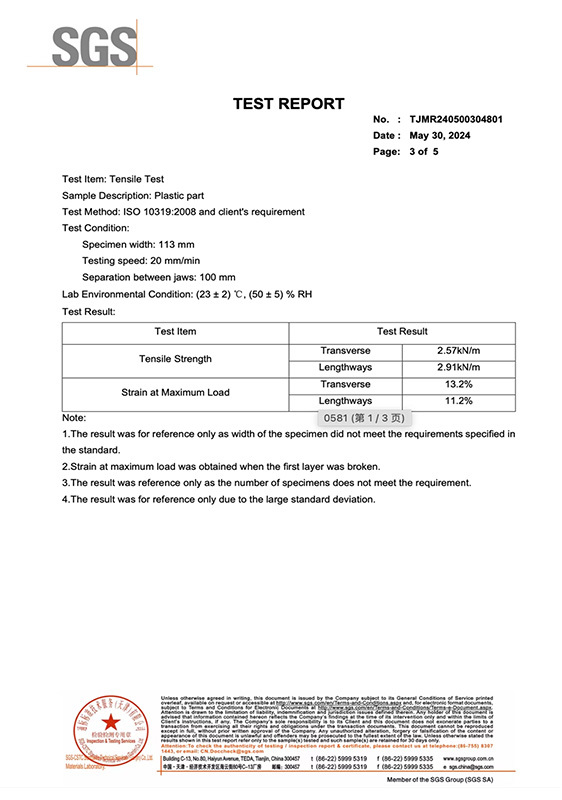

Qualifications

Company Introduction

Now our company has employees 83production machinery more than 70 sets, with a total area of 30,000 square meters, the production process instrict accordance with lSO9001: 2000 standards and certification.Our products include: Decoraive Wire Mesh, Diamond Metal Lath, Rib lath, Hy Rib Formwork, ConstructionExpanded Metal Mesh In Rol, Brick Mesh, Corner Bead, Fiberglass Mesh, Perforated Metal Sheet, ExpandedMetal Mesh, Welded Wire Mesh, Welded Mesh Panel, Fence Mesh, Stainless Steel Kind Kong Wire MeshExpanded Metal Mesh for Insert Netting, Aluminum Perforated Security Door Mesh, and so on.

Exhibition Updates

We are active in major exhibitions around the world and are committed to providing customers with professional metal mesh solutions. The guiding principle of company quality is "Quality is life" and " lmprove quality and no endless".in addition toestablishing the quality policy, quality procedures, but in all the plant into sophisticated detection equipment, tostrengthen inspection work, every second to achieve the maximum quide lines. And to "insist on doing is to dothe best"business philosophy, expanded to hearts of every employee, making our company continued prosperityand sustainable industry beyond the source.

Key words:

Related Products