Black Iron Wire

- 产品描述

-

This is Black Iron Wire, also known as black annealed wire. Here's a detailed introduction:

Production Process

Made from low - carbon steel wire rods, it goes through a wire - drawing process. By pulling the rods through dies of different diameters, it can be made into various diameters (from extremely fine wires like hair to thicker construction - grade wires). Some are also annealed to reduce hardness and enhance flexibility for easier bending and shaping later.

Properties

1.Hardness & Toughness: Classified into hard and soft types. Hard black iron wire has high strength and rigidity, not easy to deform, suitable for scenarios needing shape retention. Soft (annealed) wire has good flexibility, easy to bend and bundle, common in daily binding.

2.Surface & Rust Resistance: No plating on the surface, so it’s prone to rust in humid or corrosive environments, limiting long - term outdoor use. But this also makes it cost - effective for low - rust - requirement, budget - conscious applications.

Applications

1.Construction: Used to tie steel bars, fixing the position of steel bar frameworks. It’s a basic and high - consumption item in construction. Hard wire ensures the stability of the steel structure. Also used for temporary safety nets, formwork support, etc.

2.Daily Bundling: Soft black iron wire is popular in logistics, agriculture for its ease of use—bundling cartons, packages, or securing crop straws, vines. Low - cost and convenient.

3.Craft Making: Handicraft enthusiasts use it for simple iron art (like wire paintings, small decorations). Its flexibility allows shaping, and though rust - prone, painting or aging treatments can give unique textures.

Pros & Cons

1.Advantages: Low cost, simple production, affordable price; diverse forms (various thicknesses, hardness) for different needs; soft type is easy to process, meeting flexible operation demands.

2.Disadvantages: Poor rust resistance, requiring extra protection (oiling, painting) for long - term outdoor use; hard type has low flexibility, easy to break when bent, needing careful handling.

We Support Customized Services Regardless Of Material And Model Please Tell Me Your Needs

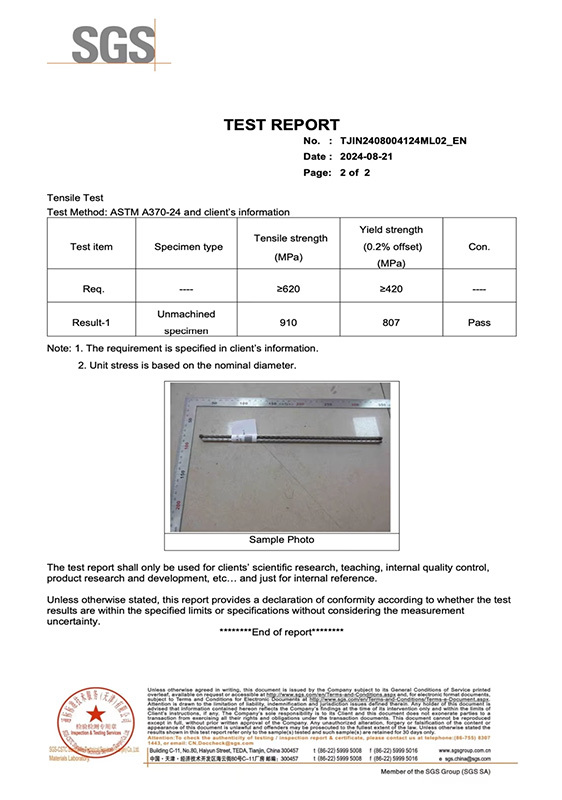

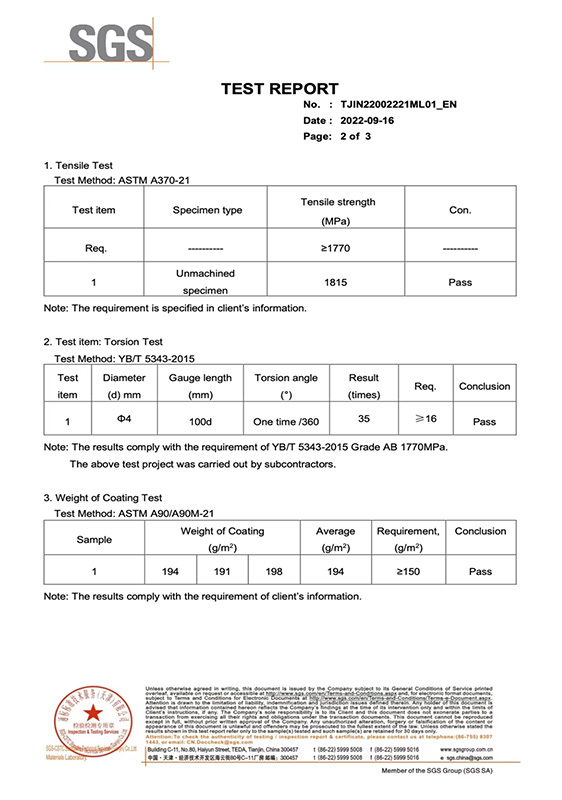

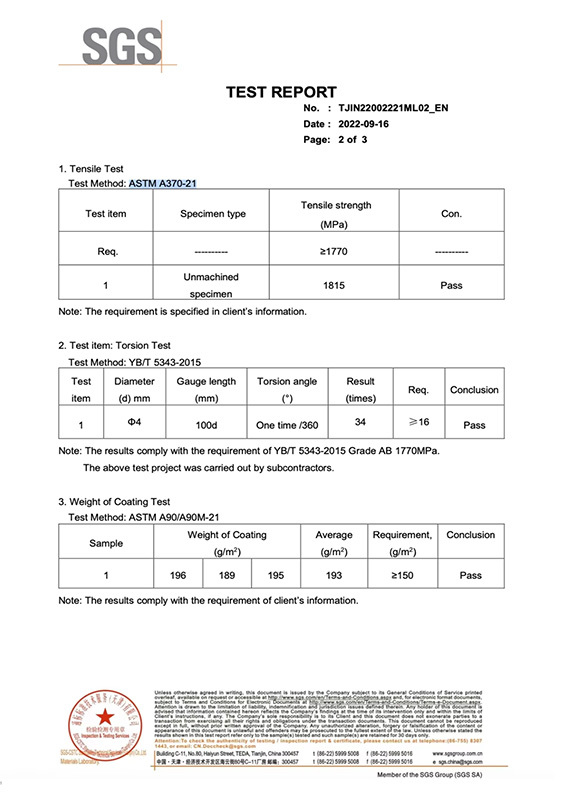

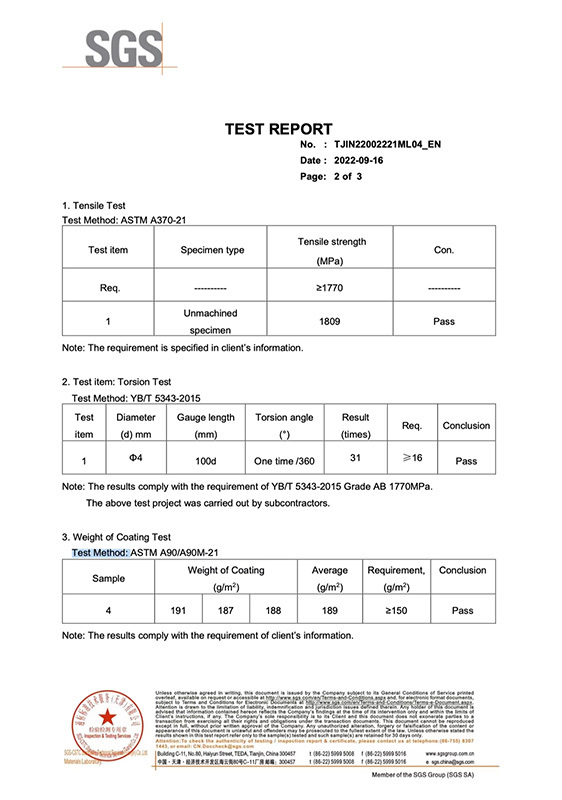

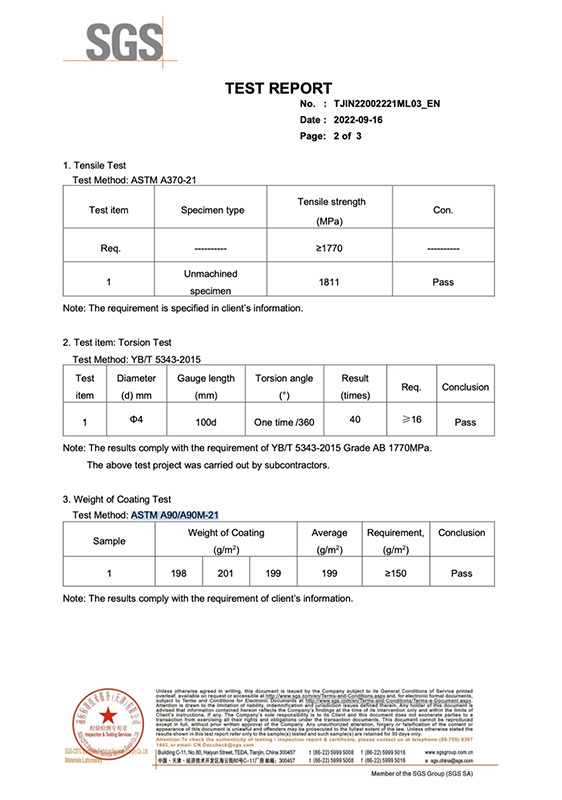

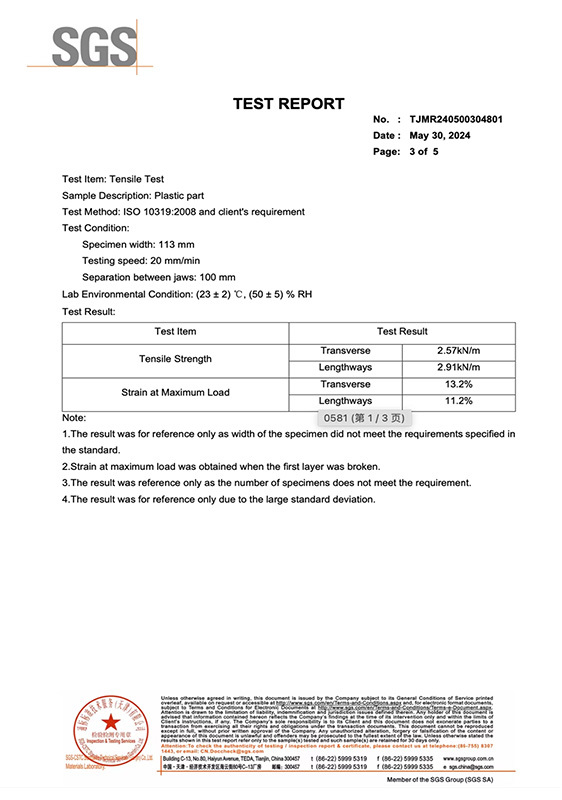

Qualifications

Company Introduction

Now our company has employees 83production machinery more than 70 sets, with a total area of 30,000 square meters, the production process instrict accordance with lSO9001: 2000 standards and certification.Our products include: Decoraive Wire Mesh, Diamond Metal Lath, Rib lath, Hy Rib Formwork, ConstructionExpanded Metal Mesh In Rol, Brick Mesh, Corner Bead, Fiberglass Mesh, Perforated Metal Sheet, ExpandedMetal Mesh, Welded Wire Mesh, Welded Mesh Panel, Fence Mesh, Stainless Steel Kind Kong Wire MeshExpanded Metal Mesh for Insert Netting, Aluminum Perforated Security Door Mesh, and so on.

Exhibition Updates

We are active in major exhibitions around the world and are committed to providing customers with professional metal mesh solutions. The guiding principle of company quality is "Quality is life" and " lmprove quality and no endless".in addition toestablishing the quality policy, quality procedures, but in all the plant into sophisticated detection equipment, tostrengthen inspection work, every second to achieve the maximum quide lines. And to "insist on doing is to dothe best"business philosophy, expanded to hearts of every employee, making our company continued prosperityand sustainable industry beyond the source.

Key words:

Related Products