Hexagonal Mesh

- 产品描述

-

Hexagonal Metal Mesh, also known as Hex Mesh or Honeycomb Mesh, is a mesh product made from metal wires, which are woven into a regular hexagonal grid structure by mechanical processes. Its unique geometric structure endows the product with excellent stability, pressure resistance, and flexibility, making it widely used in various fields such as construction, aquaculture, transportation, and water conservancy.

Basic Information

1.Product Name: Hexagonal Metal Mesh

2.Core Structure: Adopts a regular hexagonal grid (honeycomb-shaped) design with uniform mesh size; the wire diameter can be customized according to actual needs.

3.Common Alternative Names: In Chinese, common alternative names include Hex Mesh and Honeycomb Metal Mesh; in some regions, it is also called Diamond Mesh.

Core Structure and Parameters

1. Structural Features

●Advantages of Hexagonal Grid: The hexagon is a highly stable geometric structure in nature (e.g., beehives, tortoise shells). It can evenly disperse external forces, and compared with square or diamond meshes, it has stronger tensile and impact resistance, and is not prone to deformation during long-term use.

●Mesh Surface Form: Mainly divided into two types: roll form and sheet form. Roll-shaped products usually have a length of 5-50 meters and a width of 0.5-2.4 meters; the size of sheet-shaped products can be customized according to specific customer needs (e.g., 1m × 2m, 2m × 3m, etc.).

2. Key Parameters

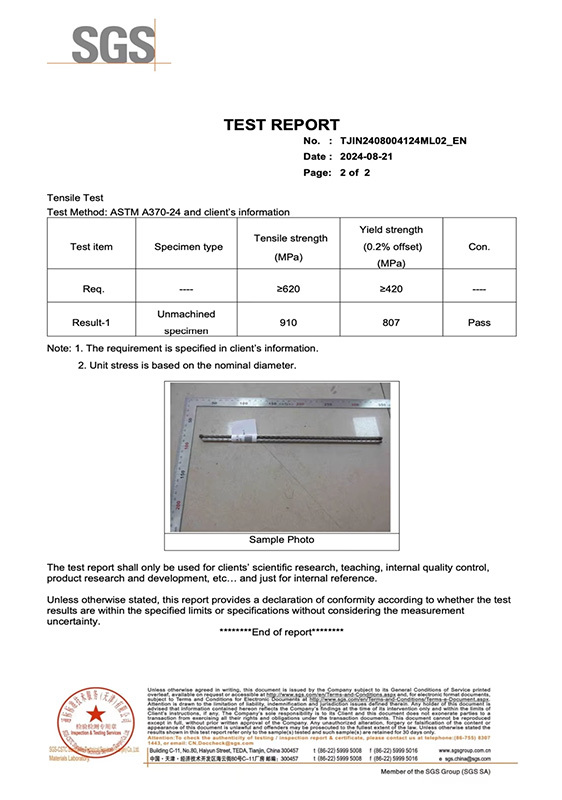

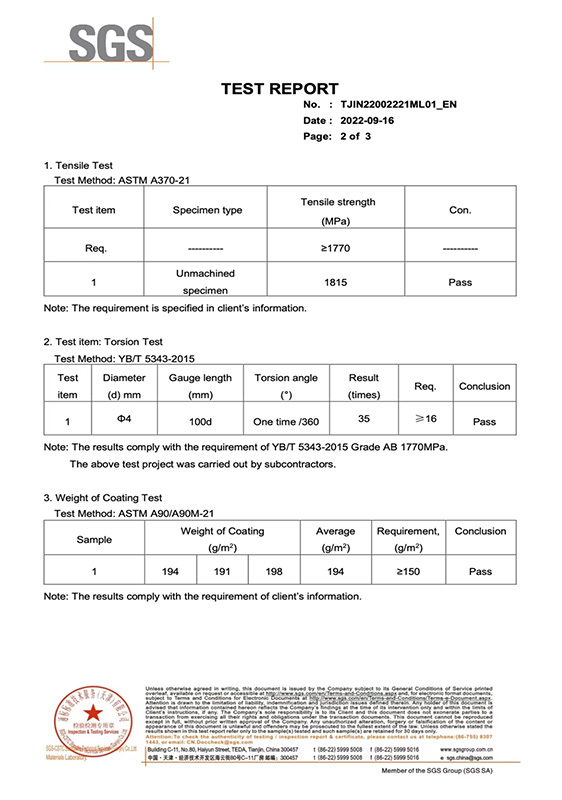

●Wire Diameter: Refers to the diameter of the metal wire, which directly determines the strength of the mesh. The common range is: 0.5-4.0 mm for low carbon steel wires, and 0.3-2.0 mm for stainless steel wires.

●Mesh Size: Usually measured by the distance between opposite sides of the hexagonal grid, with a common range of 10-100 mm (e.g., common specifications such as 12 mm, 25 mm, 50 mm).

●Mesh Width: Refers to the horizontal dimension of the mesh surface. The width of roll-shaped products is generally 0.5-2.4 meters, and the width of sheet-shaped products can be customized.

●Mesh Length: Refers to the vertical dimension of the mesh surface. The length of roll-shaped products is usually 5-50 meters, and the length of sheet-shaped products can be customized according to requirements.

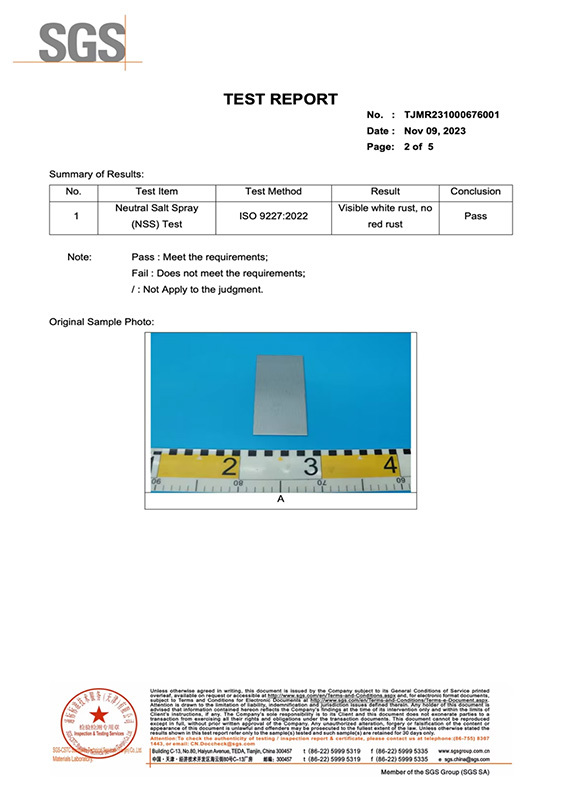

●Surface Treatment: Processes adopted to improve the rust and corrosion resistance of the mesh. Common types include galvanization, plastic spraying, plastic dipping, and painting.

Material Classification

1.Low Carbon Steel (Black Wire): Its core characteristics are low cost and high strength, but it is prone to rust and needs to be used with surface treatment. Applicable scenarios include temporary protection and indoor non-humid environments (e.g., shelf isolation).

2.Hot-dip Galvanized Steel: The zinc coating thickness can reach 30-80 micrometers (μm), with strong rust resistance and the ability to withstand complex outdoor environments. Applicable scenarios include outdoor building protection, water conservancy projects, and highway guardrails.

3.Electro-galvanized Steel: The zinc coating is relatively thin (5-20 μm), with a smooth surface and moderate rust resistance. Applicable scenarios include indoor decoration and light outdoor scenarios (e.g., garden fences).

4.Stainless Steel: Has extremely strong corrosion resistance and high-temperature resistance, with a long service life, but the cost is relatively high. Applicable scenarios include food processing workshops, chemical equipment protection, and facilities in coastal areas.

5.Aluminum Alloy: Lightweight, corrosion-resistant, and easy to process, but its strength is lower than that of steel. Applicable scenarios include indoor decorative partitions, auxiliary components in aerospace, and lightweight protective meshes.

Production Process

1.Raw Material Pretreatment: Metal wires first undergo rust removal (pickling or sandblasting process) and straightening treatment to ensure uniform wire diameter and smooth surface, preventing breakage during subsequent weaving.

2.Mechanical Weaving: Specialized hexagonal mesh weaving machines are used to weave warp and weft wires into a hexagonal grid. During the weaving process, equipment parameters can be adjusted to accurately control the mesh size and mesh surface width.

3.Surface Treatment: According to actual application needs, the woven mesh is subjected to treatments such as galvanization (hot-dip or electro-galvanization), plastic spraying (epoxy resin powder), and plastic dipping (PVC coating) to improve rust resistance and enhance aesthetics.

4.Cutting and Forming: The woven mesh is cut into roll or sheet forms according to customer needs. Some products require further processing (e.g., edge wrapping, punching) to facilitate subsequent installation.

Application Fields

1. Construction and Civil Engineering

●Foundation Pit Support Mesh: Used to prevent the collapse of foundation pit slopes and enhance soil stability.

●Wall Plastering Mesh: Embedded inside walls to effectively reduce wall cracking.

●Roof Fall Protection Mesh: Used for safety protection during roof construction to ensure the safety of construction workers.

2. Aquaculture and Agriculture

●Fish/Shrimp Pond Fence Mesh: Prevents the escape of aquatic farmed products and blocks the invasion of natural enemies.

●Chicken/Rabbit House Isolation Mesh: Separates different breeding areas and has good ventilation and light transmission.

●Orchard Bird Protection Mesh: Protects fruits from bird pecking and reduces yield loss.

3. Transportation and Municipal Engineering

●Highway Guardrail Mesh: Separates lanes, prevents pedestrians from crossing the road randomly, and ensures traffic order.

●Railway Protection Mesh: Blocks foreign objects from entering the railway track and reduces potential traffic safety hazards.

●Municipal Greening Fence Mesh: Divides green areas and prevents pedestrians from trampling and damaging vegetation.

4. Water Conservancy and Environment

●Riverbank Slope Protection Mesh: Fixes the soil on the riverbank, prevents soil erosion, and protects the river ecosystem.

●Sewage Treatment Filter Mesh: Filters impurities in sewage and improves sewage treatment efficiency.

●Tailings Dam Protection Mesh: Reinforces the structure of tailings dams and reduces the risk of dam failure.

5. Decoration and Industry

●Indoor Partition Mesh: Used for space division in places such as shopping malls and restaurants, with both aesthetics and transparency.

●Equipment Protection Mesh: Wraps industrial machinery to prevent personnel from accidentally touching dangerous components.

●Art Decorative Mesh: Customized in color and mesh style, used in decorative scenarios such as walls and ceilings to enhance the artistic sense of the space.

We Support Customized Services Regardless Of Material And Model Please Tell Me Your Needs

Qualifications

Company Introduction

Now our company has employees 83production machinery more than 70 sets, with a total area of 30,000 square meters, the production process instrict accordance with lSO9001: 2000 standards and certification.Our products include: Decoraive Wire Mesh, Diamond Metal Lath, Rib lath, Hy Rib Formwork, ConstructionExpanded Metal Mesh In Rol, Brick Mesh, Corner Bead, Fiberglass Mesh, Perforated Metal Sheet, ExpandedMetal Mesh, Welded Wire Mesh, Welded Mesh Panel, Fence Mesh, Stainless Steel Kind Kong Wire MeshExpanded Metal Mesh for Insert Netting, Aluminum Perforated Security Door Mesh, and so on.

Exhibition Updates

We are active in major exhibitions around the world and are committed to providing customers with professional metal mesh solutions. The guiding principle of company quality is "Quality is life" and " lmprove quality and no endless".in addition toestablishing the quality policy, quality procedures, but in all the plant into sophisticated detection equipment, tostrengthen inspection work, every second to achieve the maximum quide lines. And to "insist on doing is to dothe best"business philosophy, expanded to hearts of every employee, making our company continued prosperityand sustainable industry beyond the source.

Key words:

Related Products