Expanded Metal Mesh panel

- 产品描述

-

Product Introduction

Black diamond - hole expanded metal mesh with a frame. It is manufactured via the "slitting and stretching" integrated process: first, continuous slits are cut on a metal sheet along diamond contours, then the sheet is stretched to form a mesh with regular diamond holes. After that, it undergoes black coating treatment (such as powder coating or dip coating) and is equipped with a frame to enhance structural stability. It integrates multiple functions like protection, ventilation, and decoration, and is widely used in industries, architecture, electronic equipment, etc.

Core Features and Process

1.Manufacturing Process: Using the "slitting and stretching" technology, metal sheets (such as low - carbon steel, stainless steel, aluminum plates, etc.) are cut into diamond slits by CNC equipment and then stretched to form a mesh. The material utilization rate exceeds 95%. The surface is treated with black powder coating (coating thickness: 60 - 120μm) or dip coating (coating thickness: 200 - 300μm), which has strong weather resistance and can be used for a long time in environments from -50℃ to 120℃, suitable for outdoor humid and sunny scenarios.

2.Material Options:

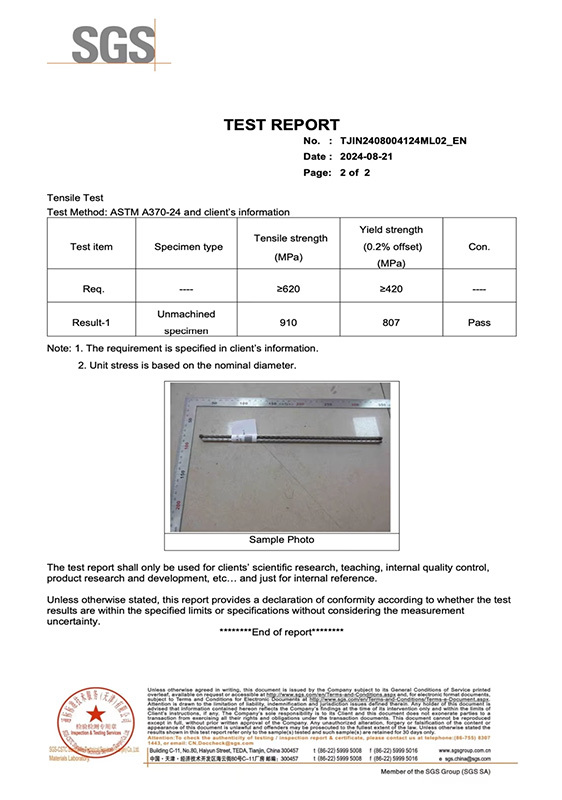

●Low - carbon steel (Q235): Low cost and high strength (tensile strength: 500 - 800MPa), mostly used for industrial protection (such as equipment guards, construction site fences).

●Stainless steel (304/316): High temperature resistance (≤600℃) and excellent corrosion resistance, suitable for harsh environments such as marine and chemical industries, and can also be used for high - end decoration or medical equipment protection.

●Aluminum plate (1060/5052): Lightweight (density: 2.7g/cm³) and good thermal conductivity, suitable for scenarios such as building facades and electronic heat dissipation components.

3.Structural Design:

●Diamond hole specifications: The pitch (distance between opposite sides of the diamond) is 5 - 25mm, and the strand width (width of the metal wire at the edge of the mesh hole) is 0.5 - 2.5mm. The transparency reaches 60% - 80%, and it can bear 500 - 1000kg/m², taking into account ventilation and load - bearing.

●Frame support: The metal frame is integrated with or spliced and fixed to the mesh surface to enhance the overall structural stability and facilitate modular installation (such as splicing with buckles or bolts).

Application Scenarios

1.Industrial Protection: Machinery guards (such as lathes, generator air inlet nets, preventing debris from entering while ensuring ventilation); scaffold planks (replacing traditional bamboo slats, anti - slip, fire - resistant, and can be reused for more than 10 times).

2.Architectural Decoration: Building facades, ceilings (using the light and shadow effect of black diamond holes to create an industrial or light luxury feel, with a light transmittance of more than 60%, achieving "separation without complete blocking" for space transparency and privacy protection); indoor partitions (such as office and hotel screens, enhancing the scene atmosphere with lighting).

3.Electronic and Special Fields: Dust nets for electronic equipment (such as server chassis filters, filtering dust while shielding electromagnetic interference); automotive grilles (such as off - road vehicle bumpers, balancing protection and air intake efficiency); speaker grilles (black matte coating improves texture, and diamond holes ensure sound penetration).

Performance Advantages

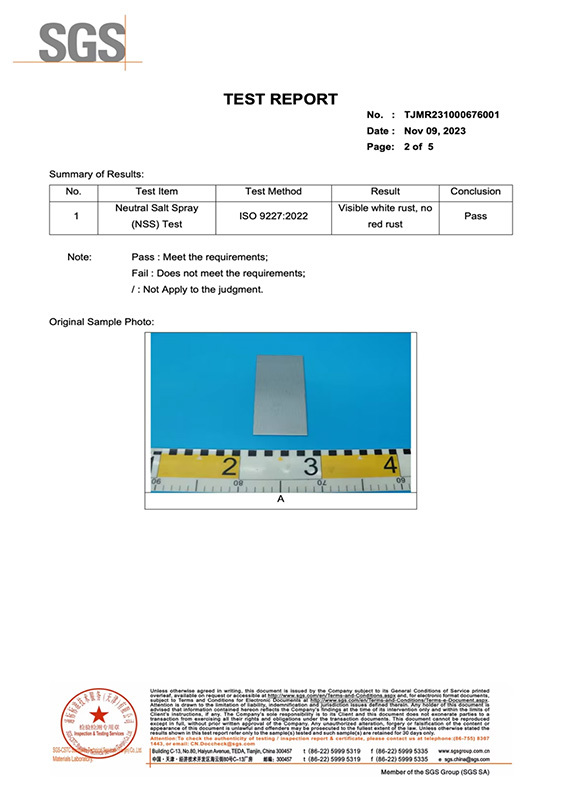

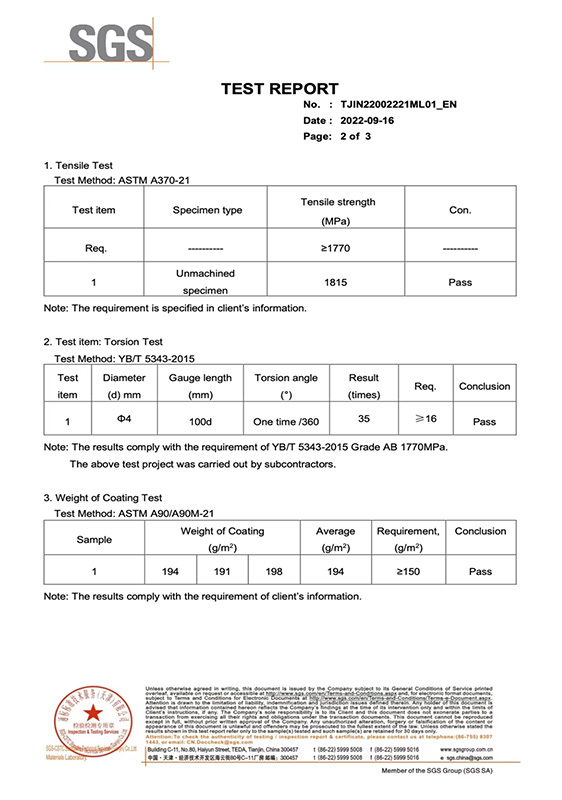

1.Durability: Low - carbon steel has a service life of 10 - 15 years after powder coating, and stainless steel versions can last more than 20 years, with no rust after 480 hours of salt spray testing.

2.Versatility: It meets the needs of protection (fall prevention, debris blocking), ventilation (air circulation rate exceeds 70%), and decoration (black matte texture adapts to various styles) at the same time.

3.Economy: The modular design is convenient for reuse, with a material recovery rate of 85%, and the long-term maintenance cost is 60% lower than that of traditional wire mesh.

We Support Customized Services Regardless Of Material And Model Please Tell Me Your Needs

Qualifications

Company Introduction

Now our company has employees 83production machinery more than 70 sets, with a total area of 30,000 square meters, the production process instrict accordance with lSO9001: 2000 standards and certification.Our products include: Decoraive Wire Mesh, Diamond Metal Lath, Rib lath, Hy Rib Formwork, ConstructionExpanded Metal Mesh In Rol, Brick Mesh, Corner Bead, Fiberglass Mesh, Perforated Metal Sheet, ExpandedMetal Mesh, Welded Wire Mesh, Welded Mesh Panel, Fence Mesh, Stainless Steel Kind Kong Wire MeshExpanded Metal Mesh for Insert Netting, Aluminum Perforated Security Door Mesh, and so on.

Exhibition Updates

We are active in major exhibitions around the world and are committed to providing customers with professional metal mesh solutions. The guiding principle of company quality is "Quality is life" and " lmprove quality and no endless".in addition toestablishing the quality policy, quality procedures, but in all the plant into sophisticated detection equipment, tostrengthen inspection work, every second to achieve the maximum quide lines. And to "insist on doing is to dothe best"business philosophy, expanded to hearts of every employee, making our company continued prosperityand sustainable industry beyond the source.

Key words:

Related Products