Filter Basket

- 产品描述

-

A metal woven mesh filter frame is a device used to filter impurities in liquids or gases, consisting of a metal woven mesh and a frame. The following is a detailed introduction to it:

Structural composition

1.Metal woven mesh: It is the core part of the filter frame, made of metal wires through weaving process, such as stainless steel wire, galvanized steel wire, copper wire, etc. The weaving methods include plain weave, diagonal weave, mat weave, etc. Different weaving methods determine the pore size, uniformity, and strength of the mesh to meet different filtration accuracy requirements.

2.Framework: Used to support and fix metal woven mesh to maintain a stable shape, making it easy to install and use. The frame material is usually matched with the woven mesh material, commonly including stainless steel, aluminum alloy, etc. It has a certain strength and corrosion resistance, and can withstand the pressure during the filtration process.

Characteristic

1.High filtration accuracy: Metal woven mesh with suitable mesh size and weaving method can be selected according to different needs to achieve various precision requirements from coarse filtration to fine filtration, effectively intercepting impurity particles of various sizes.

2.High strength and wear resistance: The metal material endows the filter frame with high strength and hardness, which can withstand certain pressure and impact forces, and is not easily deformed or damaged; At the same time, the surface of the metal woven mesh is relatively smooth, with good wear resistance and extended service life.

3.Strong corrosion resistance: Made of corrosion-resistant metal materials such as stainless steel and galvanized, it can resist the erosion of chemicals such as acid, alkali, and salt, and is suitable for various harsh working environments, such as chemical, electroplating, sewage treatment, and other industries.

4.Good breathability and permeability: The pore structure of the metal woven mesh allows gases and liquids to pass smoothly, without causing excessive resistance during the filtration process, ensuring filtration efficiency.

5.Washable and reusable: After a period of use, impurities on the filter frame can be removed by cleaning, restoring the filter frame to its original filtering performance, thereby reducing the cost of use and meeting environmental requirements.

Application area

1.Industrial filtration: used in industries such as chemical, petroleum, pharmaceutical, food and beverage to filter various liquid raw materials, intermediates, and finished products, removing solid impurities, particles, suspended solids, etc., to ensure product quality and smooth production processes. For example, filtering medicinal liquids in the pharmaceutical industry and filtering fruit juice, beer, etc. in the food and beverage industry.

2.Air filtration: Used for air filtration in air conditioning systems, ventilation equipment, clean rooms, and other places, it can effectively filter pollutants such as dust, pollen, and smoke in the air, provide a clean air environment, and ensure people's health and the normal operation of equipment.

3.Water treatment: Used in fields such as water treatment plants, sewage treatment plants, and industrial wastewater treatment to filter impurities such as sediment, rust, and organic matter in water and improve water quality. It can also be used for water quality filtration in swimming pools, landscape pools, etc., to maintain the clarity and transparency of water.

4.Other fields: In metallurgy, mechanical processing, aerospace and other fields, it is also widely used, such as filtering lubricating oil, hydraulic oil, coolant, etc., to protect the normal operation of equipment and extend the service life of equipment.

Maintenance

1.Regular cleaning: According to the usage environment and frequency, regularly clean the metal woven mesh filter frame to remove surface impurities and dirt. When cleaning, methods such as rinsing with clean water, ultrasonic cleaning, or chemical cleaning can be used, but it is important to choose the appropriate cleaning solution to avoid corrosion of the metal mesh and frame.

2.Inspection and replacement: Regularly inspect the damage of the filter frame. If the metal woven mesh is found to be damaged, deformed, severely blocked, or the frame has cracks or looseness, it should be replaced or repaired in a timely manner to ensure the filtering effect and safety.

3.Storage method: When not in use, the metal woven mesh filter frame should be stored in a dry, well ventilated environment to avoid moisture, rust, and mechanical damage.

We Support Customized Services Regardless Of Material And Model Please Tell Me Your Needs

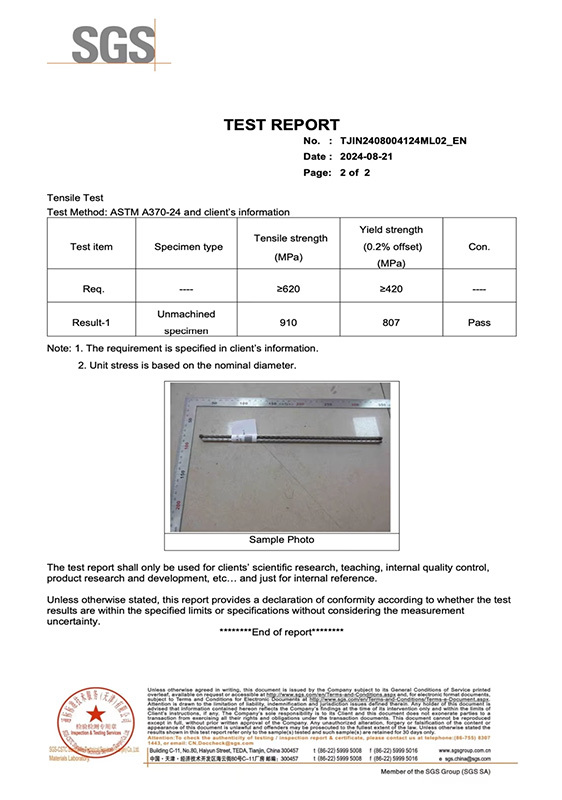

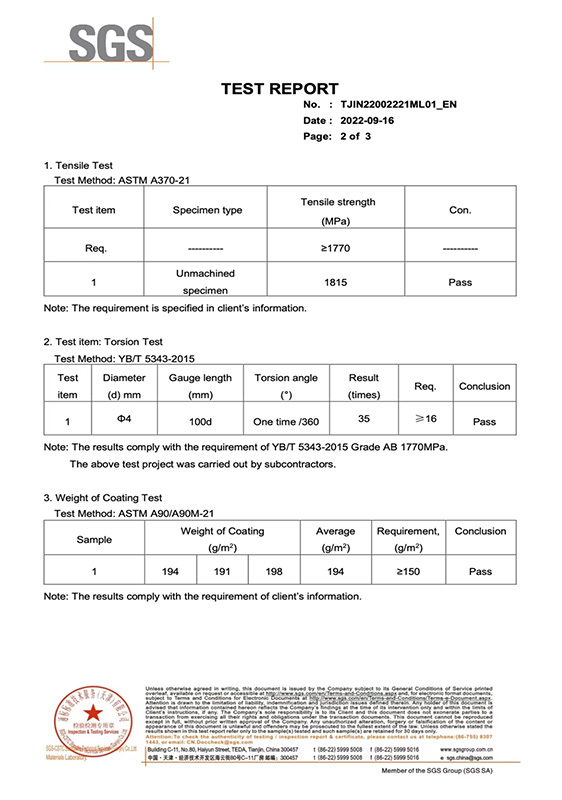

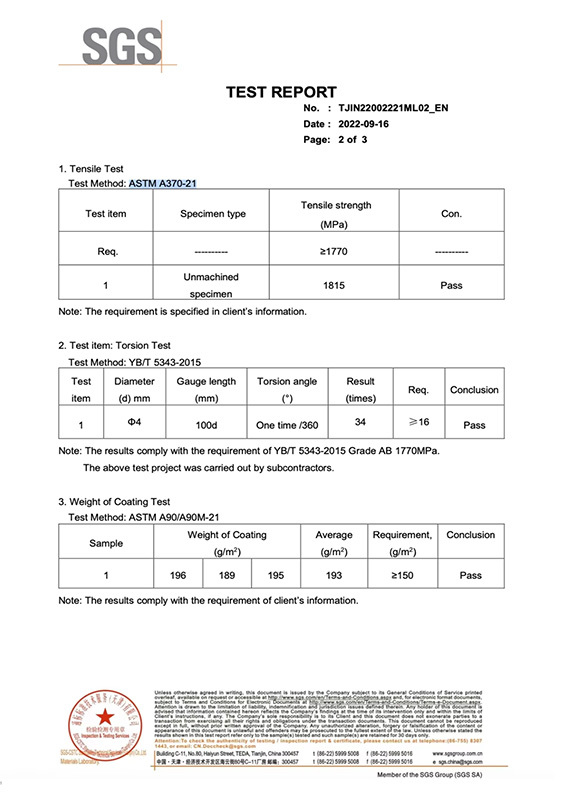

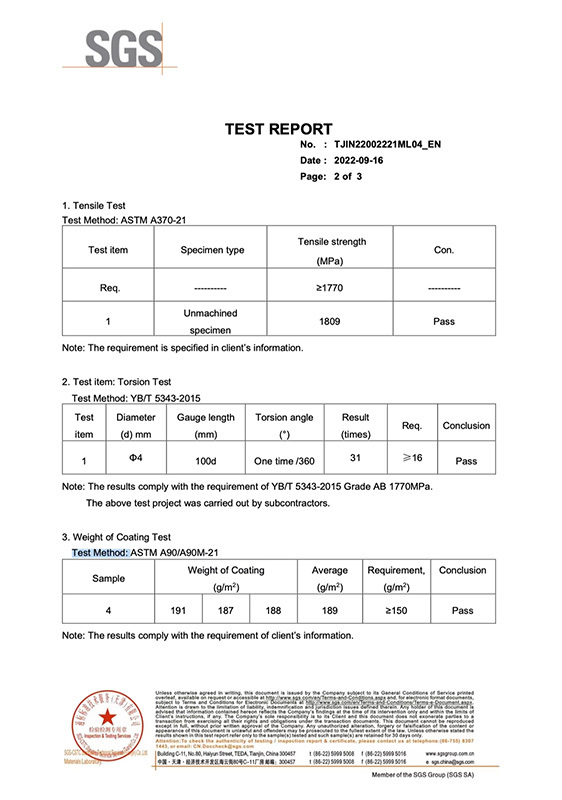

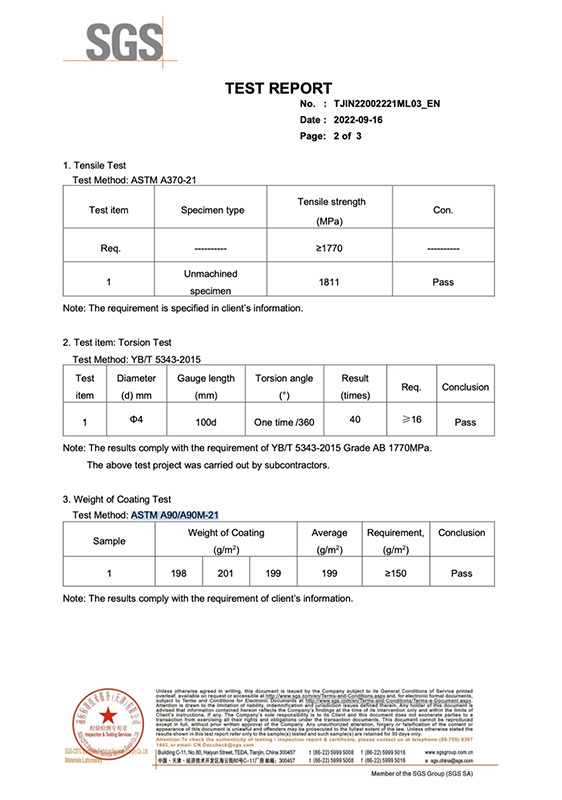

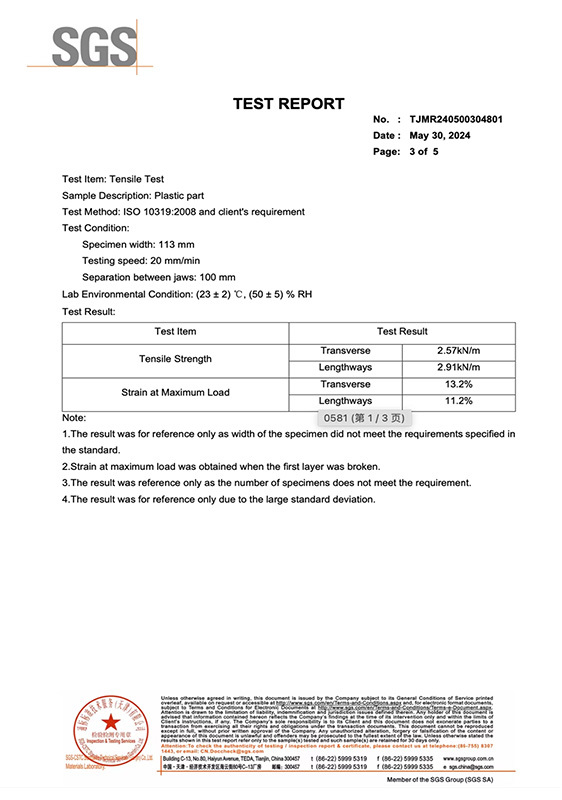

Qualifications

Company Introduction

Now our company has employees 83production machinery more than 70 sets, with a total area of 30,000 square meters, the production process instrict accordance with lSO9001: 2000 standards and certification.Our products include: Decoraive Wire Mesh, Diamond Metal Lath, Rib lath, Hy Rib Formwork, ConstructionExpanded Metal Mesh In Rol, Brick Mesh, Corner Bead, Fiberglass Mesh, Perforated Metal Sheet, ExpandedMetal Mesh, Welded Wire Mesh, Welded Mesh Panel, Fence Mesh, Stainless Steel Kind Kong Wire MeshExpanded Metal Mesh for Insert Netting, Aluminum Perforated Security Door Mesh, and so on.

Exhibition Updates

We are active in major exhibitions around the world and are committed to providing customers with professional metal mesh solutions. The guiding principle of company quality is "Quality is life" and " lmprove quality and no endless".in addition toestablishing the quality policy, quality procedures, but in all the plant into sophisticated detection equipment, tostrengthen inspection work, every second to achieve the maximum quide lines. And to "insist on doing is to dothe best"business philosophy, expanded to hearts of every employee, making our company continued prosperityand sustainable industry beyond the source.

Key words:

Related Products