Anti - Tank Metal Wire

- 产品描述

-

Anti - tank metal wire, also known as tank - blocking wire, which plays an important role in military defense.

Structure and Material

1.Structure: Usually, high - strength metal wires are interwoven and twined with each other to form a relatively complex mesh structure. A common form is a honeycomb - like mesh hole shape. This structure makes the metal net have a certain degree of flexibility and ductility. Meanwhile, when subjected to external impact, it can disperse the force and is not easily damaged.

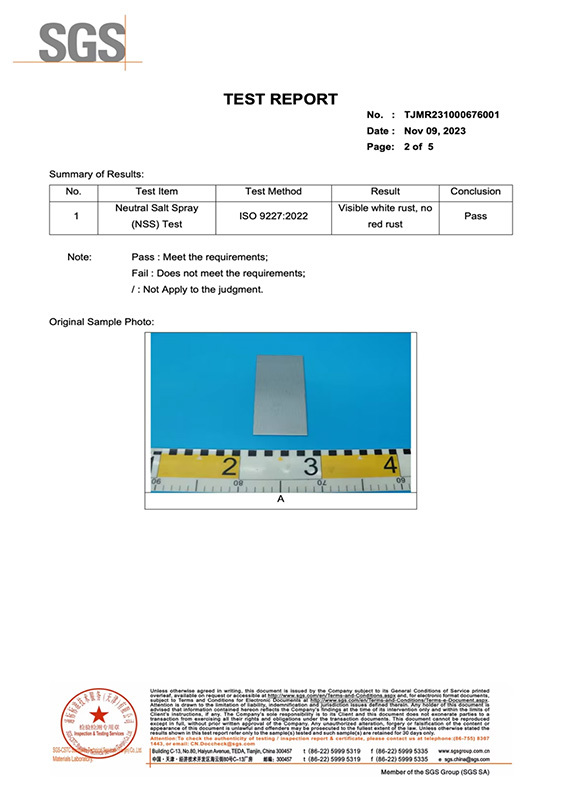

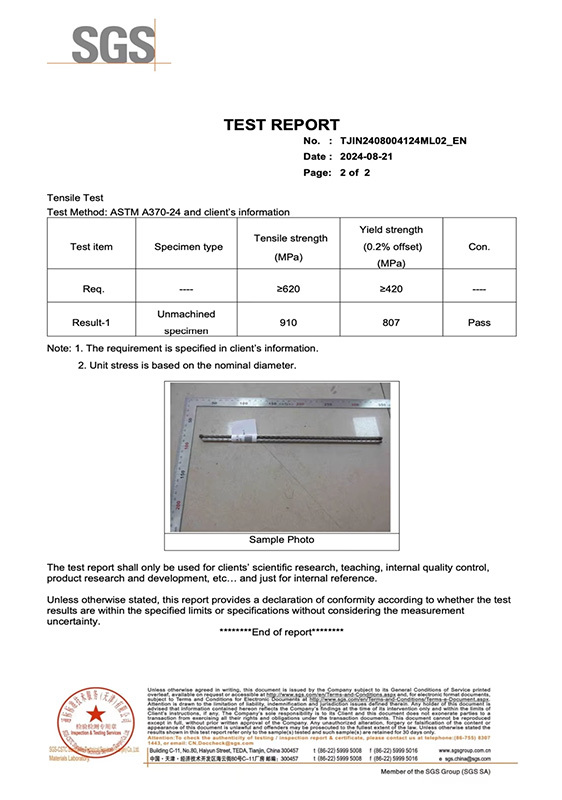

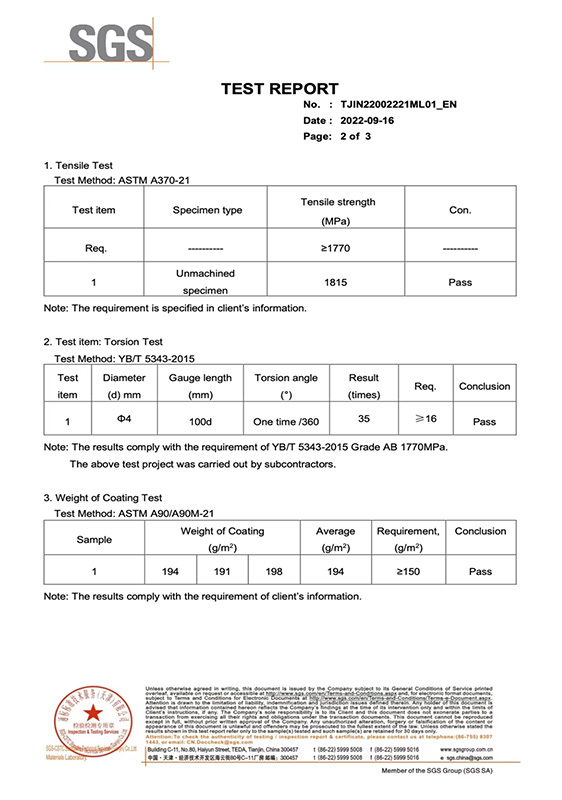

2.Material: Mainly made of metal materials such as stainless steel wires and high - strength steel wires. These materials have the characteristics of high hardness and strong toughness, and can withstand the rolling and dragging of tank tracks without being easily broken or deformed. Some metal mesh will also be subjected to anti - rust treatment, such as galvanizing and coating with anti - rust paint, to extend its service life in the field environment.

Working Principle

1.Mechanical Obstruction: When a tank tries to roll over or rush through the anti - tank metal mesh, the metal wires will wind around key parts such as the tank's tracks, road wheels, and suspension systems. The winding of the metal wires will increase the resistance of track rotation, causing the tracks to slip and be unable to move normally. Meanwhile, the metal wires may also get stuck in the gaps between the tracks and road wheels, further hindering the rotation of the tracks and making the tank unable to move.

2.Damage to Components: During the interaction between the metal wires and tank components, the sharp metal wires may cut the rubber tracks of the tank, or damage vulnerable components such as hydraulic pipelines and cables in the suspension system, causing the tank to lose its mobility or part of its combat functions.

Application Scenarios and Deployment

1.Application Scenarios: Often used in the front of military defense positions, such as border defense lines, around important military facilities, etc., to delay or prevent the attack of enemy tanks. It can also be set at key intersections and around buildings in urban street - fighting environments to restrict the movement of enemy armored vehicles and create favorable combat conditions for one's own troops.

2.Deployment Methods: It can be manually laid. Soldiers can unfold and fix the anti - tank metal wires on the ground according to the actual terrain and defense needs; it can also be quickly deployed by mechanical devices for throwing and spreading. For example, a special launching device can be used to lay it over a large area in a short time, improving defense efficiency.

Limitations and Countermeasures

1.Limitations: To a certain extent, the defense effect of the anti - tank metal wire depends on correct deployment and maintenance. If the deployment position is improper, it may not be able to effectively block the tank; and in severe weather conditions (such as strong winds, heavy rains, heavy snows, etc.), the metal wire may shift, be damaged, etc., affecting its performance. In addition, for tanks equipped with advanced obstacle - clearing equipment (such as mine plows, bulldozer blades, etc.), the obstruction effect of the metal wire will be weakened.

2.Countermeasures: By combining with other defense works, such as anti - tank trenches, minefields, etc., a multi - level defense system is built to enhance the comprehensive defense ability against enemy tanks. At the same time, the anti - tank metal wire is regularly inspected and maintained to ensure that it is always in good working condition. For tanks equipped with obstacle - clearing equipment, a stronger and more complex metal wire structure can be adopted, or special components for anti - cutting and anti - bulldozing can be added to the metal wire.

We Support Customized Services Regardless Of Material And Model Please Tell Me Your Needs

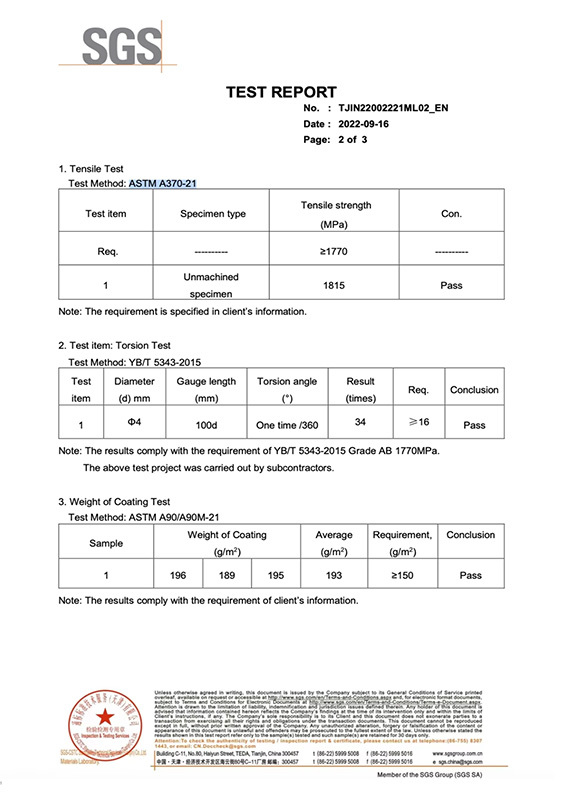

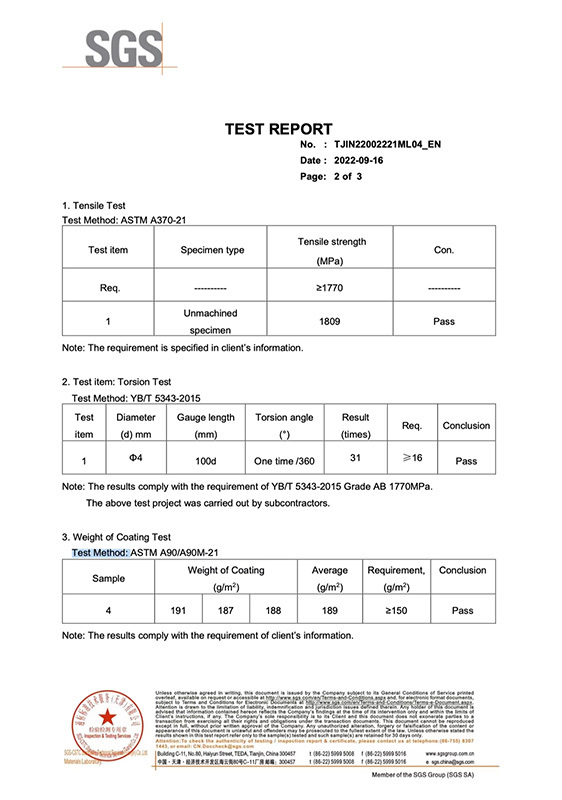

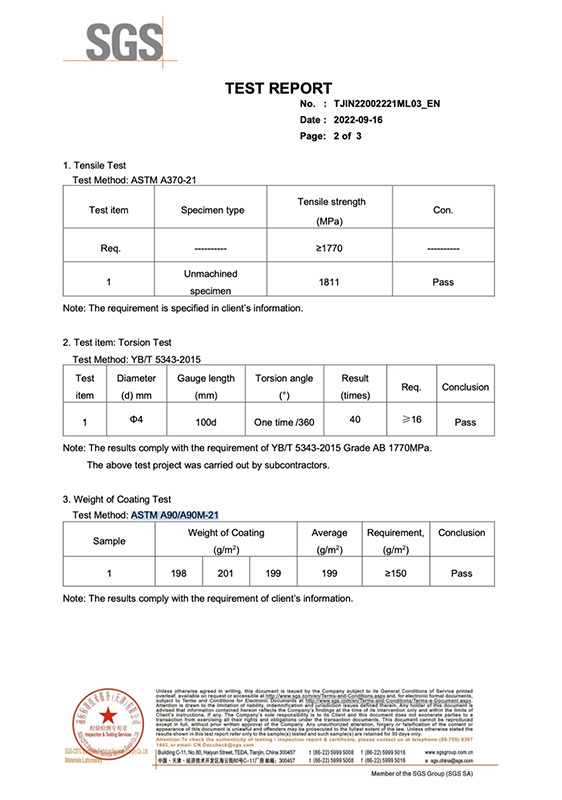

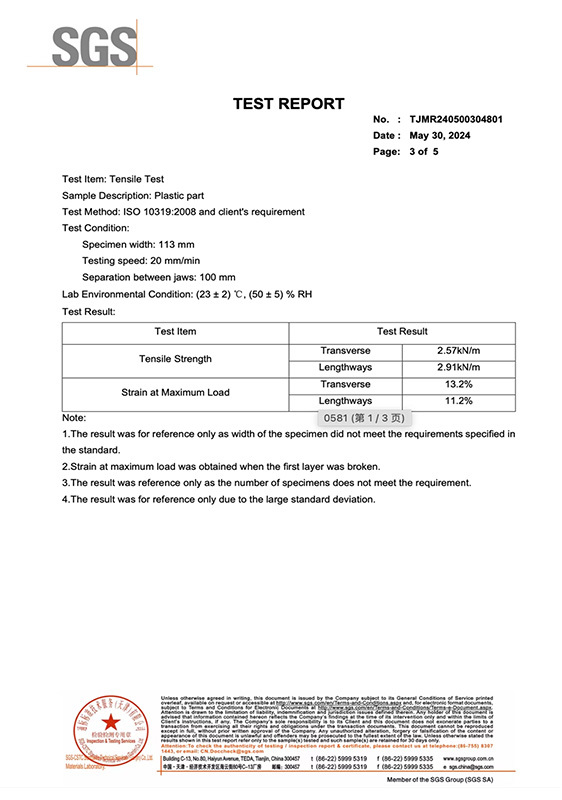

Qualifications

Company Introduction

Now our company has employees 83production machinery more than 70 sets, with a total area of 30,000 square meters, the production process instrict accordance with lSO9001: 2000 standards and certification.Our products include: Decoraive Wire Mesh, Diamond Metal Lath, Rib lath, Hy Rib Formwork, ConstructionExpanded Metal Mesh In Rol, Brick Mesh, Corner Bead, Fiberglass Mesh, Perforated Metal Sheet, ExpandedMetal Mesh, Welded Wire Mesh, Welded Mesh Panel, Fence Mesh, Stainless Steel Kind Kong Wire MeshExpanded Metal Mesh for Insert Netting, Aluminum Perforated Security Door Mesh, and so on.

Exhibition Updates

We are active in major exhibitions around the world and are committed to providing customers with professional metal mesh solutions. The guiding principle of company quality is "Quality is life" and " lmprove quality and no endless".in addition toestablishing the quality policy, quality procedures, but in all the plant into sophisticated detection equipment, tostrengthen inspection work, every second to achieve the maximum quide lines. And to "insist on doing is to dothe best"business philosophy, expanded to hearts of every employee, making our company continued prosperityand sustainable industry beyond the source.

Key words:

Related Products