Maximize Storage Efficiency with Customized Warehouse Shelving Mesh Solutions

Nov 01,2025

Maximize Storage Efficiency with Customized Warehouse Shelving Mesh Solutions

In the ever-evolving landscape of warehousing and storage solutions, efficiency is key. As businesses grow, so does the demand for organized, accessible storage systems. Customized warehouse shelving mesh solutions stand at the forefront of this transformation, offering flexibility, durability, and tailored configurations to meet diverse needs. This comprehensive guide will delve into the myriad benefits of these innovative shelving systems and provide actionable insights for maximizing storage efficiency.

Understanding Warehouse Shelving Mesh Solutions

Warehouse shelving mesh solutions are designed to optimize vertical and horizontal storage space, ensuring that every square foot of your warehouse is utilized effectively. These systems are constructed from sturdy materials, often featuring a mesh design that enhances airflow and visibility, making it easier to manage inventory. Let’s explore the key components and advantages of these shelving solutions.

What are Mesh Shelving Systems?

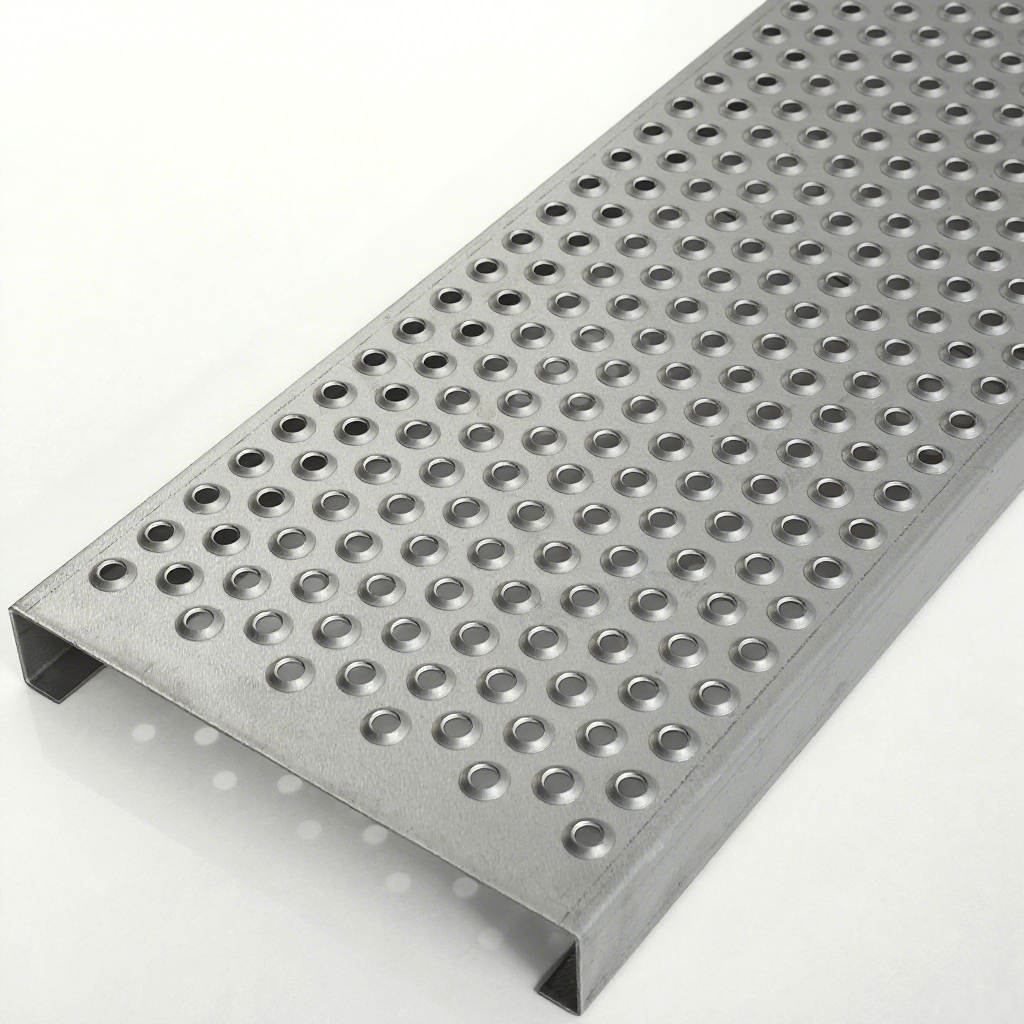

Mesh shelving systems consist of a series of shelves made from steel or other durable materials, designed with a mesh pattern that allows for air circulation and visibility. This design prevents dust accumulation and provides a clear view of stored items, reducing the time spent searching for products. With customized options, businesses can create shelving units that perfectly fit their inventory requirements.

Key Features of Customized Mesh Shelving

- Adjustable Heights: Easily modify shelf heights to accommodate various product sizes, maximizing the use of vertical space.

- Durable Construction: Made from high-quality materials that withstand heavy loads, ensuring longevity and reliability.

- Enhanced Airflow: The mesh design promotes ventilation, preventing moisture buildup and preserving product integrity.

- Versatile Configurations: Tailor shelving layouts to fit specific warehouse dimensions and operational needs.

- Easy Assembly: Many mesh shelving systems come with intuitive assembly instructions, allowing for quick setup.

The Importance of Customization in Warehouse Shelving

Every warehouse has unique requirements based on the types of products stored, the size of the facility, and the workflow processes in place. Customizing your shelving solutions can significantly enhance overall efficiency. Here’s why.

Maximizing Space Utilization

Through customization, businesses can design shelving systems that utilize every inch of available space. This is particularly beneficial in warehouses with irregular layouts or specific storage needs. Custom solutions can help to:

- Utilize vertical space to its fullest potential.

- Incorporate shelving into existing structures or areas that may otherwise be underutilized.

- Adapt to seasonal inventory changes or fluctuating stock levels.

Improving Workflow Efficiency

Custom shelving solutions can streamline operations by optimizing the flow of goods. With strategically placed shelves, employees can easily access items, reducing the time spent picking and packing. This leads to:

- Faster order fulfillment.

- Reduced labor costs.

- Higher employee satisfaction due to a more organized workspace.

Benefits of Customized Mesh Shelving Solutions

Investing in customized mesh shelving systems offers a multitude of benefits that can significantly enhance warehouse performance.

Enhanced Visibility and Accessibility

The mesh design of these shelving systems allows for clear visibility of inventory, making it easier for employees to locate items quickly. This is particularly advantageous for warehouses with a vast array of products. Enhanced visibility leads to:

- Fewer errors in order picking.

- Improved inventory tracking.

- Reduced time spent on stocktaking.

Cost-Effectiveness

While the initial investment in customized shelving may seem significant, the long-term savings associated with improved efficiency and reduced labor costs make it a smart financial decision. Additionally, durable materials mean fewer replacements and repairs, leading to lower overall maintenance costs.

Adaptability to Changing Needs

As businesses evolve, so do their storage requirements. Customized mesh shelving systems can adapt to these changes easily. Whether expanding inventory or downsizing, these shelving solutions can be reconfigured without the need for a complete overhaul.

Choosing the Right Customized Mesh Shelving Solutions

To maximize the benefits of mesh shelving, it’s essential to choose the right solutions tailored to your specific needs. Here are some considerations to keep in mind.

Assess Your Storage Requirements

Begin by evaluating your inventory types and quantities. This assessment will guide you in selecting the appropriate shelving configurations, heights, and materials. Consider factors such as:

- The weight of items to be stored.

- Dimensions of the products.

- Frequency of access to different items.

Consult with Experts

Engaging with warehouse storage specialists can provide valuable insights. They can offer recommendations based on industry trends and best practices, ensuring you make informed decisions. Experienced consultants can also assist in designing layouts that optimize workflow and efficiency.

Evaluate Material Options

Selecting the right materials is crucial for durability and functionality. Common materials for mesh shelving include:

- Steel: Known for its strength and load-bearing capacity, steel shelving is ideal for heavy items.

- Plastic: Lightweight and resistant to moisture, plastic shelving can be suitable for specific storage scenarios.

- Wire Mesh: Offers excellent visibility and airflow, making it perfect for perishable goods.

Installation and Maintenance of Mesh Shelving Systems

Proper installation and maintenance are vital for ensuring the longevity and effectiveness of your customized shelving solutions.

Installation Best Practices

When installing mesh shelving, follow these best practices to ensure optimal performance:

- Ensure a level surface for stability.

- Follow manufacturer instructions for assembly to avoid safety hazards.

- Regularly check for loose bolts or connectors to maintain structural integrity.

Routine Maintenance Tips

Maintaining your shelving systems is essential for maximizing their lifespan. Consider these maintenance tips:

- Regularly clean shelves to prevent dust buildup.

- Inspect for signs of wear or damage.

- Reorganize items periodically to ensure weight distribution is even.

Case Studies: Successful Implementation of Customized Mesh Shelving

Examining real-world examples of businesses that have successfully implemented customized mesh shelving can provide valuable insights into the benefits and considerations involved.

Case Study 1: A Retail Warehouse Transformation

A major retail company faced challenges with inventory management due to a lack of visibility and organization. After implementing customized mesh shelving solutions, they reported:

- A 30% decrease in order fulfillment time.

- Improved accuracy in inventory counts.

- Enhanced employee morale due to a more organized environment.

Case Study 2: Streamlining Operations in a Manufacturing Facility

A manufacturing facility struggled with inefficient use of space and slow retrieval times for materials. By investing in tailored mesh shelving, they achieved:

- Increased storage capacity without expanding the facility.

- Faster access to critical materials, reducing downtime.

- Significant cost savings through improved efficiency.

Frequently Asked Questions (FAQs)

1. What are the advantages of using mesh shelving over traditional shelving?

Mesh shelving offers improved visibility, better airflow, and customizable configurations, making it more versatile for diverse storage needs compared to traditional shelving.

2. How do I determine the best height for my mesh shelving?

Consider the size of your products and the frequency of access. Adjustable shelving is recommended for flexibility in height.

3. Are customized mesh shelving solutions cost-effective?

While they may require a higher initial investment, the long-term savings from increased efficiency and reduced labor costs make them cost-effective.

4. Can mesh shelving be used for heavy items?

Yes, many mesh shelving systems are designed to support heavy loads, especially when constructed from durable materials like steel.

5. How often should I perform maintenance on my mesh shelving?

Regular inspections and cleaning should be carried out monthly to ensure safety and longevity. Address any wear or damage immediately.

Conclusion

In the world of warehousing, **maximizing storage efficiency** is not simply a goal; it is a necessity for sustainable growth. Customized warehouse shelving mesh solutions offer a powerful answer to the challenges of space utilization, organization, and workflow efficiency. By investing in tailored shelving systems, businesses can enhance visibility, improve operational efficiency, and create a more organized working environment. From assessing storage needs to consulting with experts, the steps taken toward implementing customized solutions can lead to transformative results. As the demands of inventory management continue to evolve, so too should the strategies employed to meet them. Embracing customized mesh shelving is a proactive step toward a more efficient and productive warehouse.

PREVIOUS: